Basic Information about the Laboratory:

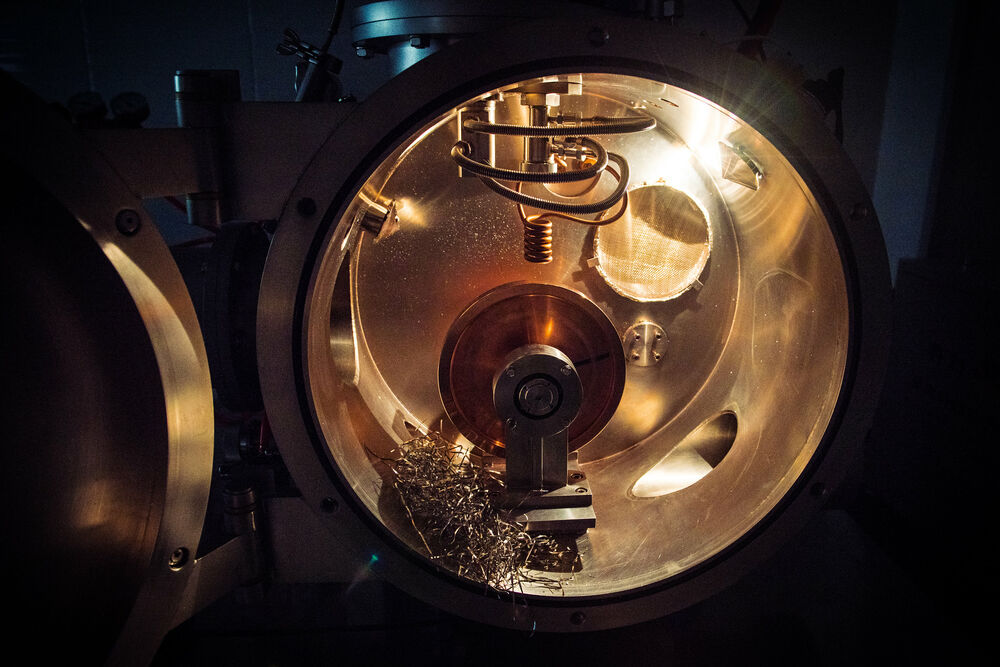

The Laboratory of Non-Conventional Energy-Efficient Materials is a world-class laboratory set up to obtain new non-equilibrium functional materials and iron-based coatings in order to extend their areas of application. The project is aimed at developing iron-based amorphous and nanocrystal alloys to be used as magnetic, structured and anti-radiation materials and coatings.

Activities of the Laboratory

The laboratory was established to obtain and study new non-equilibrium functional materials and iron-based coatings in order to extend their areas of application.

The key activities of the laboratory are listed below:

- development of high-permeability iron-based amorphous and nanocrystal materials with an increased complex of magnetic and mechanical features;

- elaboration of iron-based volume metallic glasses for functional coatings of high corrosive and wear resistance, and

- generation of new iron-based alloys without the base addition agent (the so-called pseudo-high entropy alloys) with a high level of technological and mechanical properties.

The project is intended to create the infrastructure permitting to achieve a considerable improvement in researching and developing new iron-based amorphous and nanocrystal alloys with improved functional features to be used as magnetic cores, solid coatings and anti-radiation materials.

The implementation of the said project allows generating:

- new high-permeability iron-based amorphous alloys with the high saturation intensity (over 1.7 Tl) and high corrosive resistance, which will allow increasing the energy-efficiency and durability of devices;

- new nanocrystal iron-based alloys with the high saturation intensity (over 1.8 Tl) and high processability and flexibility under bending, which will allow reducing losses in transformer cores;

- iron-based volume metallic glasses with the high glass-forming ability and coatings with the high mechanical performance, corrosive and wear resistance; and

- iron-based materials with the ultra-high corrosive and wear resistance, durability and resistance to damage caused by radiation treatment.

Metallic glasses are among the materials characterized by an interesting combination of features that are used in various manufacturing sectors. Iron-based metallic glasses are very attractive in terms of their soft magnetic features with quite a high saturation intensity, high electrical resistance and low cost of materials as compared to other metals. It is common knowledge that volume metallic glasses have a much higher durability, hardness and wear resistance as compared to their crystal peer-products. Therefore, due to their low cost, iron-based volume metallic glasses may be used in structures as well. However, iron-based volume metallic glasses have a drawback — low plasticity that is necessary for practical use, for which reason such research will also cover the development of volume metallic glasses that are concurrently characterized by the high hardness and plasticity.