Azamat Tavitov, a NUST MISIS master`s student, has presented the prototype of sneakers with a micro integral fan able to regulate the temperature inside the shoe. You can even use your phone to manage the sneakers’ heat.

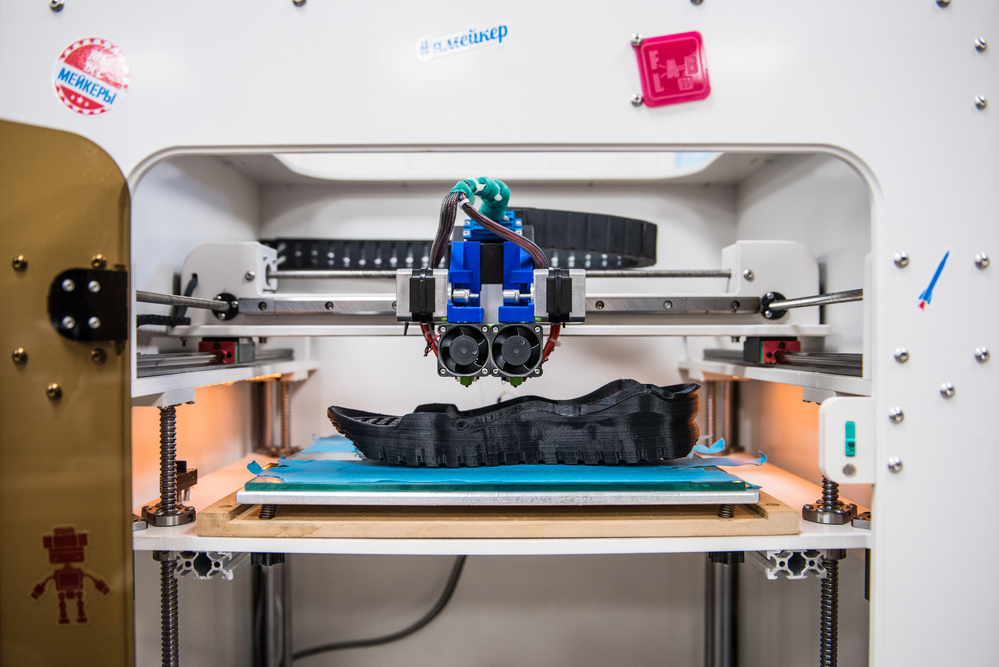

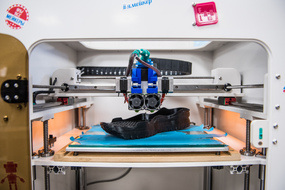

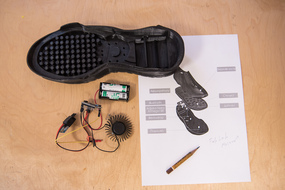

The second-year master`s student has developed a model of shoes with “air conditioning” inside. The device is produced using additive 3D printing technologies, and consists of a casing, battery power, a Bluetooth communication system and electronic control. The desired temperature inside the shoes can be set with a Smartphone.

“The idea came from the constant need for comfort on hot days. The aim of the project is to develop a device built into the shoe that is able to control the temperature inside the shoe (or other clothing items in the future). Obviously it`s not a landmark discovery since such devices have already been developed, particularly in Japan, but it is still an interesting task from an engineering solutions point of view”, said Azamat Tavitov, the Ideologist and Developer.

The development is a shoe with an elastic sole printed on a 3D printer, and inside the shoe is a ventilation system. The electronic part consists of the microcontroller ATmega168 and is connected to a system of peripheral devices: a Bluetooth module for communication with the control device (like a Smartphone), the system of micro — ventilation, and conventional batteries. The fan is charged upon receipt of a signal from the wearer`s Smartphone, and then starts to cool the sneakers.

“This development is created by students of the unique NUST MISIS program ‘Technologies and Materials for Digital Fabrication’, which is the first and only Russian master`s degree program in digital fabrication and new materials. This master`s program was jointly-launched in 2015 with the Institute for Advanced Architecture of Catalonia (IAAC) on the basis of the NUST MISIS FabLab. The program is built on the CDIO principles (Conceiving — Designing — Implementing — Operating), which contribute to the formation and development of creative skills among our university’s students”, noted Alevtina Chernikova, Rector of NUST MISIS.

The development is designed and manufactured using the 3D printer at NUST MISIS’s FabLab. During his work, Azamat Tavitov investigated properties of various polymeric materials for the production of the device’s main components. Based on his results, to work with 3D printing, he chose to work with thermoplastic elastomer FLEX, which had the necessary flexibility and easiness to work with to make the task doable.

Today, Tavitov is working on the prototype`s finalization, and is planning to begin lab tests on the sneakers by the end of 2016.