Researchers from the National University of Science and Technology “MISIS” developed a database that will help create new grades of steels. This will to speed up the process of creating innovative steel grades with specified strength and ductility allow at least 10 times, which will allow manufacturing car bodies of the most complex shapes. Article on the research is published in “Calphad”.

In modern Materials Science, the basis for the synthesis of new materials is the so-called phase state diagrams, which show the interaction of chemical elements at different temperatures. Based on this information, it is possible to predict the physical properties and microstructure of alloys, and, most importantly, the conditions and technology for their production.

By studying and collecting thermodynamic parameters, scientists create a database for use in specialized programs that allow modeling new materials. For the developers it is a kind of “cheat sheet”, according to which they develop a technology for creating new materials with the required properties.

Today, the production of flexible steels for car bodies, capable of bending into the most complex shapes, but at the same time withstands the load on impact, is very topical for the industry. It is known that the strength and ductility of steel can be increased by adding lanthanum. However, the overall mechanism of rare earth elements’ influence on steel properties remained unknown until recent times.

Thermodynamic database which describes the interaction of iron and carbon with lanthanum additives makes it possible to accurately assume the phase composition, crystallization temperature and microstructure of the material. Such a database is created by researchers from NUST MISIS. This data allows optimizing the development of new steels, as it significantly reduces the time to search for new compositions and conduct the necessary experiments. With the database, the period of development of new steel grades can be reduced from 1 year to

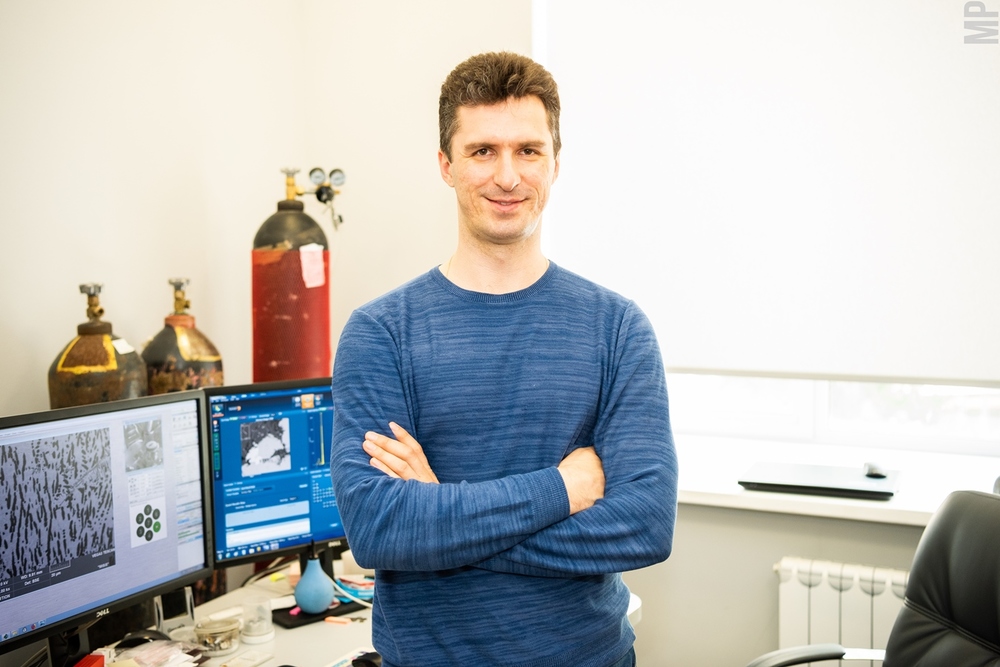

“In our work, we managed to experimentally confirm all the thermodynamic data of the La-Fe-C (lanthanum-iron-carbon) system. For instance, to clarify the chemical reactions between the elements of the system we obtained about 30 alloys with different chemical compositions”, Vladimir Cheverikin, paper co-author, senior researcher at NUST MISIS Center “Materials Termochemistry”, explains.

According to the results of the research, scientists managed to calculate the exact crystallization temperature of steel-based alloys and various changes in their heat treatment.

Thus, now, if it is necessary to create new steel grades, it is enough to load the resulting database into the appropriate software and get a list of conditions that will optimize the processes, including heat treatment and pressure treatment.