An international team of scientists with the participation of researchers from NUST MISIS has proposed an alternative filler for bone “3D-frameworks” based on calcium silicate. The material prevents the formation of a biofilm of bacteria on the surface of the framework and, in the future, can be used for implants of lightly loaded bones, such as the skull. The study was supported by a grant from the Russian Science Foundation. The results of the work were published in the scientific journal Polymer.

Nowadays, biopolymers are widely used in medicine. Development and production of polymer scaffolds — “frameworks” that serve as the basis for bone tissue restoration is the particular interest to scientists and doctors working in the field of reconstructive surgery. For better survival, such scaffolds are usually populated with the patient’s cells.

Materials for scaffolds should not only be biologically compatible with the human body, but also promote the process of tissue regeneration and have antibacterial activity — to prevent the spread of bacteria on the surface of the scaffolds. Therefore, one of the main tasks of tissue engineering is the study and creation of new materials for printing scaffolds.

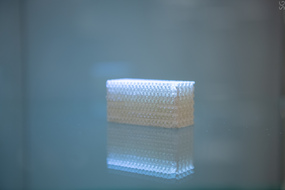

A group of scientists led by Fyodor Senatov, Director of the Research and Educational Center for Biomedical Engineering at MISIS University, and Rajan Chowdhary from Riga Technical University, produced two types of bone scaffolds using 3D printing technology based on composite materials of polylactide and wollastonite (PLA/Wol) and polylactide and hydroxyapatite (PLA/HAp).

Further, materials scientists studied the mechanical characteristics, the possibility of colonization of the printed scaffolds by multipotent mesenchymal stromal cells (MMSCs, cells close to bone tissue cells), and the antibacterial activity of the scaffolds in a physiological environment — conditions comparable to those in the body.

The results of the study showed that the chemical composition of the scaffolds significantly affects adhesion — the attachment of microbial cells to the surface.

“PLA/Wol based scaffolds showed lower mechanical performance compared to PLA/HAp scaffold. At the same time, wollastonite prevented the formation of a biofilm of Escherichia coli bacteria, and MMSCs colonized on the surface. This observation confirms that wollastonite has both bactericidal and cytocompatible properties and is an alternative filler in polymer-based composite materials for the manufacture of scaffolds using 3D printing technology,” said Vladislav Lvov, one of the authors of the study, researcher at the NUST MISIS Center for Biomedical Engineering.

In the future, such scaffolds may find their application in surgery as implants for lightly loaded bones, such as skull bones. The nearest plans of the scientific group include multiple preliminary studies and tests.