Moskovskikh Dmitry Olegovich

Moskovskikh Dmitry OlegovichPhD in engineering, director at the Research Center of Engineering Ceramic Nanomaterials

Research interests

Ultra-high-temperature ceramics, composites, high-entropy materials, silicon carbide, catalysts, self-propagating high-temperature synthesis, combustion synthesis, solution combustion, spark plasma sintering, environmentally technologies, alternative energy sources.

Field of knowledge according to the OECD classifier

2.05 — materials technologies (materials science — ceramics; materials science — composites; materials science — multidisciplinary; materials science — films and coatings; metallurgy and metals science).

01.04.00 — chemical science (inorganic and nuclear chemistry; physical chemistry; chemistry — multidisciplinary).

2018: NUST MISIS, director at the Research Center of Engineering Ceramic Nanomaterials.

2015: PhD in engineering, “Powder metallurgy and composite materials”, NUST MISIS.

2011: higher education. “Powder metallurgy, composite materials, coatings”, NUST MISIS.

Additional education

2012: higher education. “Economics and enterprise management”, NUST MISIS.

The main professional interests of Dmitry Moskovsky are related to the use of self-sustaining chemical reactions, the so-called phenomenon of “solid flame” or self-propagating high-temperature synthesis, for the synthesis of ceramic and metal nanopowders; study of the fundamental principles of their sintering and consolidation in order to obtain new materials. He is also involved in examining the direct synthesis of ceramic nano-structured materials and products by combining the processes of gasless combustion and spark plasma sintering.

Main results:

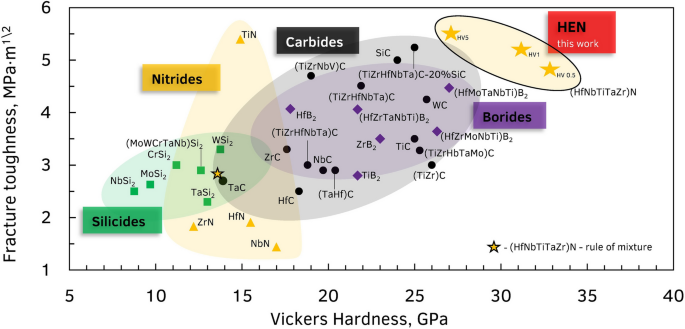

The bulk phase of high-entropy nitride (Hf0.2Nb0.2Ta0.2Ti0.2Zr0.2) N was obtained for the first time by the method of exothermic combustion. The manufactured bulk material demonstrates ultra-high hardness (33 GPa) and crack resistance (5.2 MPa m1/2), thus significantly exceeding the values of previously obtained binary and high-entropy ceramics (Fig 1). This high-entropy nitride may be used for superhard coatings, structural materials, optics, etc. The results obtained illustrate a scalable method for obtaining bulk high-entropy nitrides with new reference properties.

Fig. 1. Diagram of dependence of crack resistance and hardness with measured values for high-entropy nitride and previously obtained ceramics.

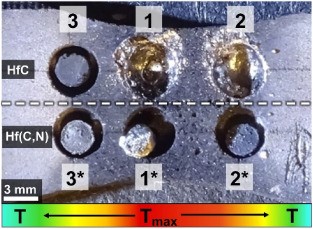

Ultra-high-temperature ceramics HfCN with the highest theoretical melting point among all currently known compounds were obtained. The melting points of the synthesized compound and the initial “record holder” — hafnium carbide were compared. To do so, pressed HfC and HfCN samples were placed on a graphite plate in the form of a dumbbell and covered with a similar plate on top to avoid heat losses. The resulting “sandwich” was connected to a powerful battery using molybdenum electrodes. All tests were carried out in high vacuum. Since the cross-section of the graphite plates varied, the maximum temperature was reached in its narrowest part. The results of simultaneous heating of the new material, carbonitride and hafnium carbide, showed that carbonitride has a higher melting point than hafnium carbide (Fig. 2).

Due to the unique combination of physical, mechanical and thermal properties, the material is promising for use in the most heat-loaded components of aircraft — nose cones, air-jet engines and sharp leading edges of the wings, operating at temperatures above 2000 °C.

Fig. 2. Macro image of a graphite heater with samples after comparative experiments on ceramic melting temperatures.

The graphene — Cu and graphene — CuNi nanocomposites were prepared by the solution combustion. Such materials are characterized by a graphene-metal nanostructure with the number of graphene layers from 1 to 3 nm and metal grains 31 nm (Cu) and 14 nm (CuNi) in size. Experimental data showed that the graphene-metal nanocomposites obtained are one of the most efficient catalysts for CO oxidation with a temperature of 100% conversion of 150 °C and 200 °C for Cu and CuNi-containing catalysts, respectively. In this case, both nanopowders turned out to be inactive with respect to the destruction of dyes.

Dmitry Moskovskikh received a scholarship from the president on the topic of self-propagating high-temperature synthesis of thermoelectric materials. The project is aimed at creating a new method for producing advanced thermoelectric materials for the power industry of the future by the method of controlled energy-efficient combustion synthesis and spark plasma sintering. To solve the problem, it is expected to do the following: create and optimize methods of synthesis by combustion of nanostructured Heusler alloys Fe2Ti1-x SnVx and Fe2TiSn1-xSix; conduct a detailed study of nanostructures depending on the synthesis conditions; determine relationships between the structure and physical properties for the manufacture of materials with the increased ZT parameter. This task is an integral part of pending issues of the energy industry of the future, the development of scientific foundations for the production of thermoelectric materials.

Scopus Hirsch Index — 12.

Number of articles on Scopus — 60.

SPIN RSCI:

ORCID: 0000-0001-5168- 4885.

ResearcherID: A-4789-2014.

Scopus AuthorID: 55511296200.

- “Development of reactive composite powders for three-dimensional spark plasma and selective laser sintering”, Ministry of Education and Science,

2019-2021. - Reactive Ti/Al and Ni/Al powders for selective laser sintering were obtained. Simulation of high-energy ball mill was carried out.

- “High-entropy ceramics and alloys — a new platform for creating materials with improved properties”, Russian Science Foundation,

2018-2021. - The bulk phase of high-entropy nitride (Hf0.2Nb0.2Ta0.2Ti0.2Zr0.2) N was obtained for the first time by the method of exothermic combustion. The manufactured bulk material demonstrates ultra-high hardness (33 GPa) and crack resistance (5.2 MPa m1/2), thus significantly exceeding the values of previously obtained binary and high-entropy ceramics.

- “Obtaining ultra-high-temperature ceramics based on hafnium carbonitride for use in extreme conditions”, Russian Science Foundation,

2019-2022. - Ultra-high-temperature ceramics HfCN with the highest theoretical melting point among all currently known compounds were obtained. The melting points of the synthesized compound and the initial “record holder” — hafnium carbide were compared.

- “New methods of manufacturing amorphous metallic and crystalline piezoelectric films for nanoelectronic devices with ultra-low power consumption”, NUST MISIS,

2018-2019. - “Development of new cutting nanostructured ceramics based on aluminum oxide with additions of silicon carbide and silicon nitride by the method of spark plasma sintering”, RFBR,

2017-2018. - “Silicon carbide nanopowder: synthesis and study of the mechanism of structure formation”, RFBR,

2014-2015. - “Nanocomposite materials on metal pseudo-alloys for contacts of switches of powerful electrical networks”, Ministry of Education and Science,

2014-2016. - “Development of new template-free methods for the synthesis of ceramic, metal and cermet materials of various morphologies”, RFBR,

2015-2016.

- Mukasyan, A.S., Moskovskikh, D.O., Nepapushev, A.A., Pauls, J.M., Roslyakov, S.I. ; Ceramics from self-sustained reactions: Recent advances (2020) Journal of the European Ceramic Society, 40 (7), pp.

2512-2526. - Buinevich, V.S., Nepapushev, A.A., Moskovskikh, D.O., Trusov, G.V., Kuskov, K.V., Vadchenko, S.G., Rogachev, A.S., Mukasyan, A.S. ; Fabrication of ultra-high-temperature nonstoichiometric hafnium carbonitride via combustion synthesis and spark plasma sintering (2020) Ceramics International, 46 (10), pp.

16068-16073. - Mukasyan, A.S., Lin, Y.-C., Rogachev, A.S., Moskovskikh, D.O.; Direct combustion synthesis of silicon carbide nanopowder from the elements (2013) Journal of the American Ceramic Society, 96 (1), pp.

111-117. - Khort, A., Romanovski, V., Leybo, D., Moskovskikh, D.; CO oxidation and organic dyes degradation over graphene—Cu and graphene—CuNi catalysts obtained by solution combustion synthesis (2020) Scientific Reports, 10 (1),

- Moskovskikh, D., Vorotilo, S., Buinevich, V., Sedegov, A., Kuskov, K., Khort, A., Shuck, C., Zhukovskyi, M., Mukasyan, A.; Extremely hard and tough high entropy nitride ceramics (2020) Scientific Reports, 10 (1),

- Rogachev, A.S., Moskovskikh, D.O., Nepapushev, A.A., Sviridova, T.A., Vadchenko, S.G., Rogachev, S.A., Mukasyan, A.S. ; Experimental investigation of milling regimes in planetary ball mill and their influence on structure and reactivity of gasless powder exothermic mixtures (2015) Powder Technology, 274, pp.

44-52. - Shkodich, N., Sedegov, A., Kuskov, K., Busurin, S., Scheck, Y., Vadchenko, S., Moskovskikh, D. ; Refractory high-entropy HfTaTiNbZr-based alloys by combined use of ball milling and spark plasma sintering: Effect of milling intensity (2020) Metals, 10 (9), статья № 1268, pp.

1-15. - Moskovskikh, D.O., Vorotilo, S., Sedegov, A.S., Kuskov, K.V., Bardasova, K.V., Kiryukhantsev-korneev, P.V., Zhukovskyi, M., Mukasyan, A.S. ; High-entropy (HfTaTiNbZr)C and (HfTaTiNbMo)C carbides fabricated through reactive high-energy ball milling and spark plasma sintering (2020) Ceramics International, 46 (11), pp.

19008-19014. - Torosyan, K.S., Sedegov, A.S., Kuskov, K.V., Abedi, M., Arkhipov, D.I., Kiryukhantsev-Korneev, P.V., Vorotilo, S., Moskovskikh, D.O., Mukasyan, A.S. ; Reactive, nonreactive, and flash spark plasma sintering of Al2O3SiC composites—A comparative study (2020) Journal of the American Ceramic Society, 103 (1), pp.

520-530. - Rogachev, A.S., Vadchenko, S.G., Kochetov, N.A., Rouvimov, S., Kovalev, D.Y., Shchukin, A.S., Moskovskikh, D.O., Nepapushev, A.A., Mukasyan, A.S. ; Structure and properties of equiatomic CoCrFeNiMn alloy fabricated by high-energy ball milling and spark plasma sintering (2019) Journal of Alloys and Compounds, 805, pp.

1237-1245.

Method for producing an ultrahigh temperature ceramic material based on hafnium carbonitride, RU 2729277, December 24, 2019, Russian Federation.

Method for obtaining a reaction composite powder of a rounded shape for use in additive technologies, 2019140909, December 11, 2019, Russian Federation.

Method for producing a carbon friction composite material based on short carbon fibers

Method for producing nanoceramics by combining self-propagating high-temperature synthesis and spark plasma sintering, Patent, priority dated December 14, 2015, Russian Federation, 20 years, No. 2614006, issue date March 22, 2017.

Nanocomposite electrical contact material and method for its production, Patent, priority date July 23, 2015, Russian Federation, 20 years, No. 2597204, issue date August 17, 2016.

Method for obtaining silicon carbide nanopowder, Patent, priority date July 20, 2012, Russian Federation, 20 years, No. 2493937, issue date September 27, 2013.

A.S. Sedegov “Development and research of high-entropy ceramic materials based on carbides of refractory elements obtained by SHS and spark plasma sintering”, 4th year postgraduate student, 2021.

Teaching

“Introduction to materials science”, online course, 10 weeks.

Reviewer of international journals Ceramic international, Journal of the European Ceramic Society, Metallurgical and Materials Transactions B: Process Metallurgy and Materials Processing Science, “Izvestiya vuzov. Non-ferrous metallurgy”.

Expert of the Russian Science Foundation.

Metals guest editor.