Materials scientists from NUST MISIS led by Professor Larisa Panina, Doctor of Physical & Mathematical Sciences, have demonstrated that microwires based on magnetic amorphous metals can be used for embedded temperature sensors. The impedance (complex resistance) of such materials is very sensitive to temperature fluctuations, and its behavior at different frequencies can significantly vary. The research paper has been published in the Journal of Magnetism and Magnetic Materials.

Amorphous metals are alloys obtained by very rapidly cooling metal melts. A high cooling rate doesn’t allow metal atoms to form crystalline grains and become ordered, which is why such materials are very different in their properties from conventional alloys. For example, the magnetocrystalline anisotropy — an effect that makes directions of magnetization more preferable — is limited in amorphous alloys due to the absence of an expressed crystal structure. Due to this, amorphous metals are soft magnetic materials which easily change their direction of magnetization.

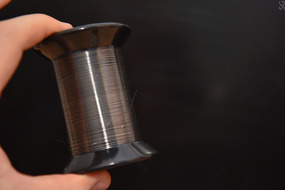

Metal wires in a glass shell are one of the materials created on the basis of amorphous metals. The features of magnetic properties in such microwires make them very sensitive to magnetic fields. For example, they have the effect of a giant magnetic impedance — a change in the material’s complex resistance to high-frequency currents in the presence of external magnetic fields.

In addition to sensitivity to external magnetic fields, the new study has shown that amorphous microwires also have a significant response to temperature changes. In particular, this applies to temperature changes near the Curie temperature alloys — a temperature at which the material completely loses its ability to maintain magnetization. It turns out that small temperature fluctuations strongly affect the magnitude of giant magnetic impedance.

Moreover, if measured at low current frequencies (up to 10 megahertz), the impedance begins to grow with the approach to the Curie temperature, and at high frequencies (300 megahertz), on the contrary, it drops.

At first, this effect was theoretically predicted by the team, and then they tested it on microwire of an amorphous alloy of cobalt, nickel, boron and silicon. The impedance measurements allowed the researchers to accurately determine the temperature in the range from 20 to 100 degrees Celsius.

Physicists suggest using microwires for integration into various industrial facilities as a temperature sensor. This will help to diagnose the condition of structures and to prevent accidents. Another potential application of the development is a medical one, as a microwire can be used for rapid diagnosis of implants.