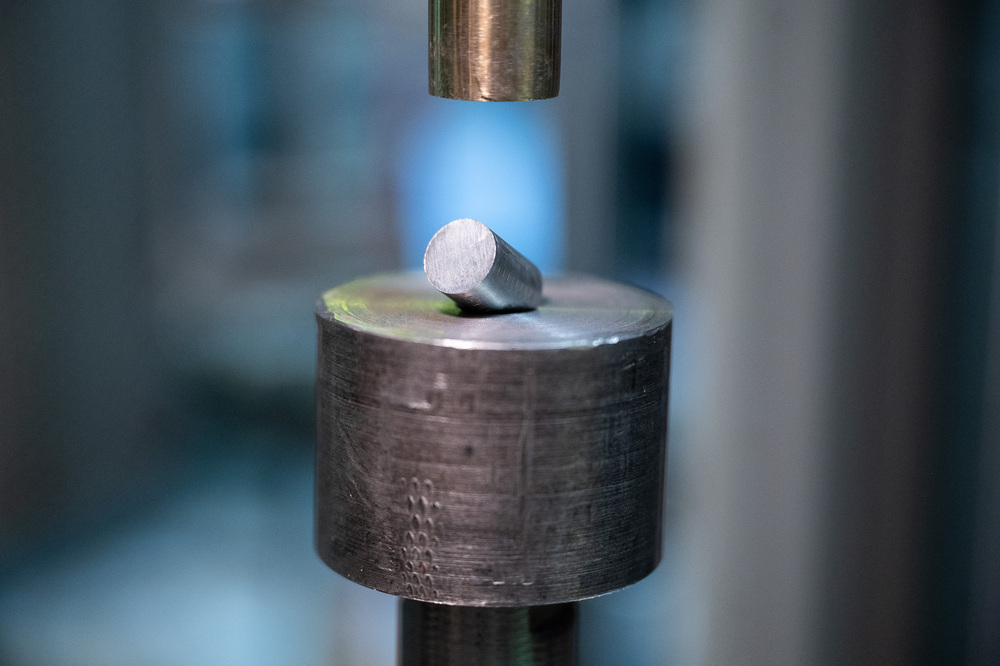

NUST MISIS researchers presented new heat-resistant composites based on aluminum alloy AA6063 for aviation and oil and gas complexes. Unlike conventional aluminum alloys, they are capable of operating at temperatures above 300°C.

Thanks to mechanical alloying, the scientists introduced ready-made aluminide particles into aluminum, which led to an increase in the heat resistance of the developed composites.

“The heat-resistant aluminum composite we have created is a promising development for use in conditions where temperatures exceed 300°C. For example, in braking systems, engines, turbines and drilling rigs. The strength limit of our materials at 300°C exceeds 240 MPa, and at room temperature it is more than 900 MPa. Such materials can become an effective replacement for heavy steels and expensive titanium alloys, which are currently used,” Alexey Proskviryakov, senior researcher at the Laboratory of Ultrafine-grained Metallic Materials at NUST MISIS.

Structural analysis after

“The obtained composite samples demonstrate high strength characteristics. Additional introduction of copper into the composite structure led to an increase in hardness from 200 HV to 300 HV,” Anastasia Mikhaylovskaya, head of the Laboratory of Ultrafine-grained Metallic Materials at NUST MISIS, PhD, research leader.

Further research by the scientists will be focused on optimising the material composition and production processes.

The study aligns with the goals of NUST MISIS’s Materials of the Future strategic project under the Russian Ministry of Science and Higher Education’s Priority 2030 program.