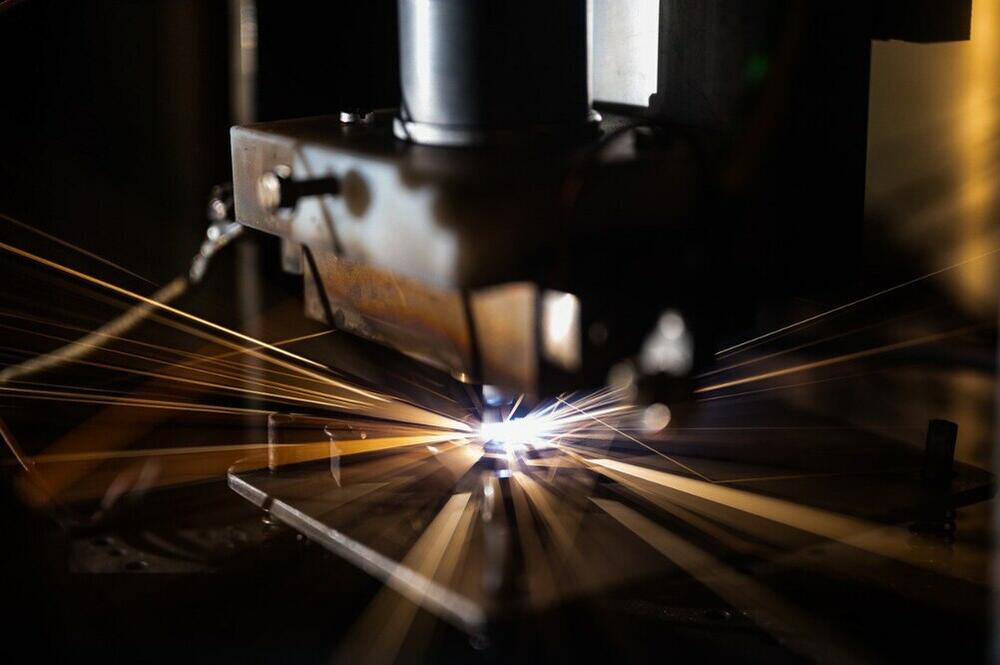

Researchers at NUST MISIS, in collaboration with colleagues from China, have introduced a new method of laser processing for hard materials to enhance their strength and selectively eliminate surface defects. This approach is particularly relevant for the aerospace industry, nuclear sector, and biophysics, as it ensures more robust structures that can withstand various external impacts.

The study demonstrated that short-pulse laser irradiation on a metal’s surface can significantly improve its mechanical properties. The technique involves the interaction of short laser pulses, approximately 20 nanoseconds in duration and with an energy of

Using computer simulations, the scientists modeled the distribution of temperatures and shock waves when a laser impacts the surface layer of a metallic alloy, considering nanoscale defects. The researchers conducted this in two stages: the first involved simulating the heating process of the surface layer with defects, and the second involved simulating the deformation and healing of nanopores in the heated material.

“As a result of the experiments, we observed an increase in the treated surface’s strength by more than 1.5 times, accompanied by enhanced resistance to cracking under localized loads ranging from 0.49 N to 4.9 N,” shared Ivan Safronov, an associate professor at the NUST MISIS Department of Physics.

The scientists consider the development of a physical mechanism for selective laser impact on defective areas (nano- and micropores) to be their most important discovery, as it significantly enhances the material’s strength. The detailed results of the study are described in Nanomaterials (Q1).

“In the future, we plan to develop implants with biocompatible surfaces that do not cause rejection or inflammation in the human body. This is eagerly awaited by doctors and patients and holds great significance for the medicine of the future,” Ivan Safronov added.

The research was supported by grants from the strategic Materials of the Future project at NUST MISIS under the Russian Ministry of Science and Higher Education’s Priority-2030 program (project no. K1—2022—027).