Researchers from Russia, China, and the United States have developed a new method for synthesizing crystalline nanowires tailored for ultra-miniature electronics. These threads, just hundreds of nanometers thick and several millimeters long, can serve as the foundation for photodetectors, solar cells, and flexible displays.

“One of the key missions of MISIS University, recognized as a global leader in materials science, is to create materials that combine the properties required for real-world industrial applications. For years, our researchers, led by Professor Pavel Sorokin, D.Sc. in Physics and Mathematics and one of the world’s top materials scientists according to Research.com, have been studying nanostructures and developing nanotechnologies. The innovative method for synthesizing crystalline nanowires proposed by this international research team will be in demand for the production of new sensors, wearable electronics, flexible displays, and more,” said Alevtina Chernikova, Rector of NUST MISIS.

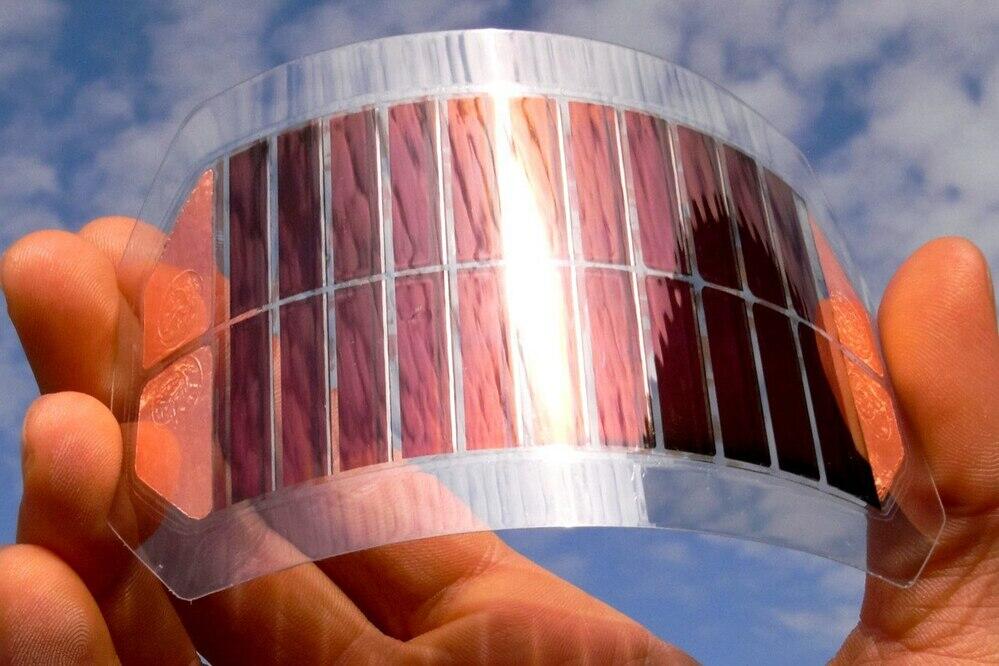

Nanowires are a special class of crystalline materials shaped like ultra-thin threads. One-dimensional nanostructures, where atoms are bonded by strong covalent links, are considered especially stable in harsh environments. Despite their potential, widespread use has been limited due to production challenges. Until now, such structures were manually separated from larger crystals. It is a low-yield process that fails to produce long, uniform samples. The wires were also prone to breaking during device integration due to their fragility.

Scientists from NUST MISIS, Tulane University, and Suzhou University of Science and Technology have proposed a new synthesis method using tantalum, nickel, and selenium. Unlike traditional approaches that place precursor powders in a single spot within the ampoule, this new technique distributes the powders evenly along the inner surface using electrostatic charging. The ampoule is then heated, and ultra-thin crystalline threads form along its walls, reaching lengths of several millimeters with diameters ranging from 100 to 400 nanometers.

“The wires were monitored for a month outside the ampoule at room temperature. Unlike most nanomaterials, which degrade under exposure to oxygen, moisture, or UV light, the structure of our wires remained intact. Moreover, they can be mechanically split into even thinner strands — down to just 7 nanometers — enabling the development of ultra-sensitive sensors and other microdevices. Quantum-chemical calculations confirmed the possibility of isolating stable individual nanowires and demonstrated their semiconducting properties,” said Konstantin Larionov, Researcher at the Laboratory of Digital Material Science at NUST MISIS.

When interfaced with nickel, stable and uniform Schottky contacts form on the surface of the wire. These are essential for devices such as photodetectors and solar cells, where high sensitivity to electric fields is required. The detailed results have been published in Scientific Reports (Q1).

“In the future, this technology could pave the way for building entire electronic circuits on a single nanowire. A millimeter-scale thread could form the basis for multiple devices in the field of molecular electronics,” concluded Professor Pavel Sorokin, Head of the Laboratory of Digital Material Science at NUST MISIS.