Researchers at NUST MISIS have created a new aluminum alloy with a unique structure tailored for the aerospace industry. By adding calcium, they managed to neutralize the harmful effects of iron impurities commonly found in recycled aluminum, transforming them into a strengthening component. In the future, this alloy could be used for aircraft skin panels.

Iron contained in recycled aluminum significantly limits its applications, as it forms brittle compounds that make the material unsuitable for high-stress components. To address this, MISIS scientists neutralized iron’s negative impact by binding it into a stable compound through calcium alloying followed by heat treatment.

“The innovations developed at NUST MISIS, the country’s leading university in advanced technologies and materials, are successfully applied across knowledge-intensive industries — from biomedicine to aviation and space. The new alloy created by our researchers combines the lightness and strength typical of aerospace materials. Thanks to its high eutectic content and stable structure, it also shows strong potential for use in 3D printing technologies,” NUST MISIS Rector Alevtina Chernikova.

“When iron appears in an aluminum alloy, it often forms sharp, needle-like crystals that make the metal brittle. Calcium addition, however, promotes the formation of a special eutectic phase and ensures a stable structure,” Dr. Torgom Akopyan, Senior Researcher at the Department of Metal Forming at NUST MISIS.

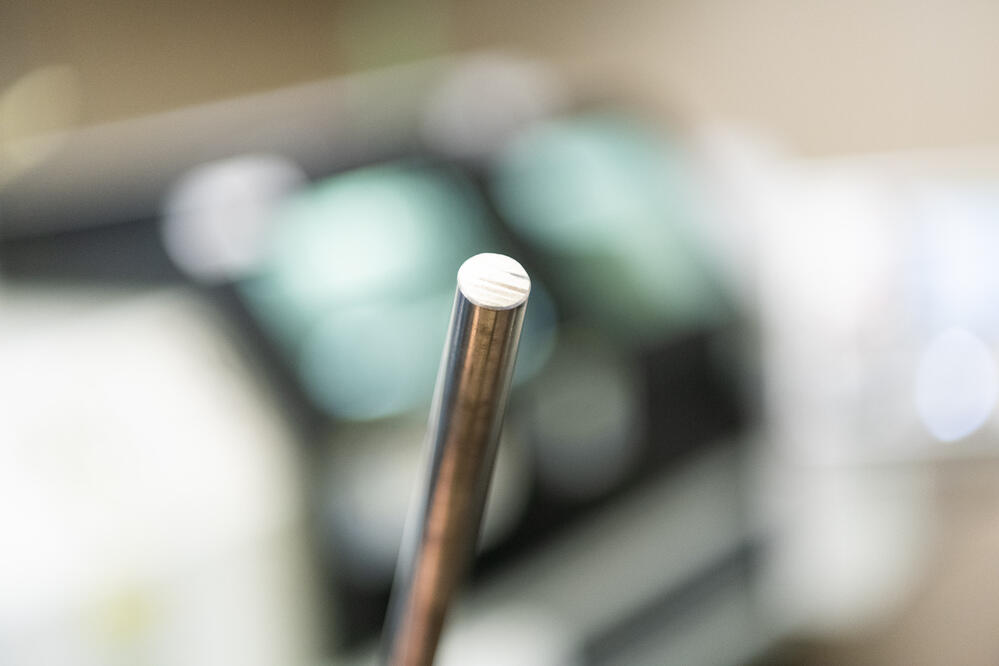

The team demonstrated that the alloy develops a new calcium-containing quaternary compound with a cubic crystal lattice and compact morphology. This enabled the production of deformed billets free of cracks and other defects. The results are published in the Journal of Alloys and Compounds (Q1).

Dr. Nikolai Belov, Chief Researcher at the Department of Metal Forming at NUST MISIS, added: “The proposed material offers an excellent balance of mechanical and processing properties, which opens up a wide range of potential applications. In the long term, it could replace the currently used wrought alloy AK4-1 (2618), which is poorly suited for 3D printing.”

The alloy’s eutectic microstructure helps reduce the risk of hot cracking during layer-by-layer solidification — a key advantage when 3D printing large parts. Industrial adoption of this development could significantly reduce production costs. Going forward, the team plans to introduce manganese, silicon, and trace amounts of zirconium into the alloy to enhance heat resistance, corrosion resistance, and overall strength.