The first full-format battery based on hybrid perovskites made entirely from domestic materials and ready for production was shown at NUST MISIS. This next-generation solar panel is cheaper in terms of production costs, with a manufacturing cycle of 8 to 10 hours. It can be installed in private homes or on industrial sites, particularly those prioritizing “green” initiatives. The panel’s design, which connects multiple sub-cells, allows for high-power generation even in shaded and cloudy conditions. This breakthrough opens new possibilities for harnessing solar energy, even in the Arctic and Far North.

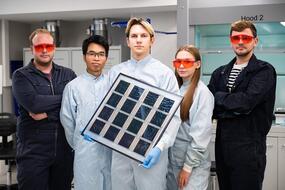

“At the MISIS University, under the Priority 2030 program, we have established and are executing the strategic project Materials of the Future, which aims to create innovative materials with specific properties. For several years, scientists at the Advanced Solar Energy Laboratory, led by PhD Danila Saranin, have been developing materials and technologies for alternative energy, conducting research on extending the lifespan and improving the efficiency of next-generation solar cells. The full-format battery based on hybrid perovskites, made entirely from domestic materials, has proven effective in low-light conditions and is fully ready for production,” Alevtina Chernikova, rector of the MISIS University.

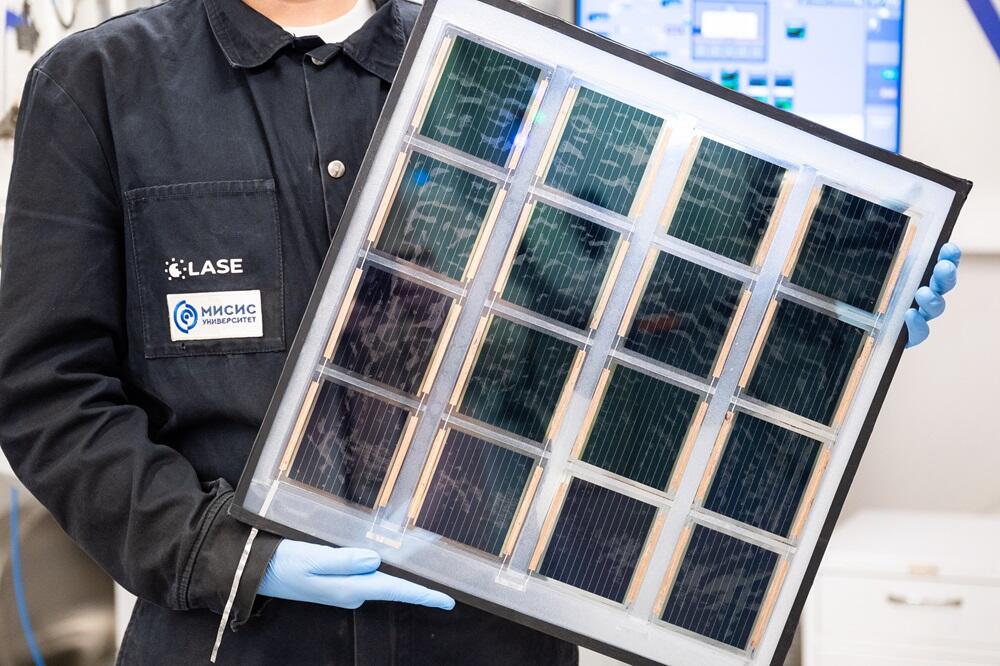

Notably, the product is made using new industrial technologies, including pulsed laser processing and crystallization of thin films in a low-pressure environment, with photoactive layers applied by liquid-phase methods. The panel is composed of 16 interconnected perovskite modules. Its housing is made of impact-resistant, chemically tempered, photovoltaic-grade glass developed by the Russian Glass Company (OJSC RSC). The unique properties of perovskites allow the panel to convert solar energy even in cloudy and low-light conditions. The panel has a power output of 7 watts and a voltage of 48 volts.

“Two years after we began developing product lines, the Advanced Solar Energy Laboratory team is presenting the first full-format panel based on hybrid perovskites, created as part of the ’Materials of the Future’ strategic project under the Priority 2030 program. While we previously showcased individual components—modules and cells—this is now a fully-fledged product ready for pilot testing on rooftops and solar power stations. This is a real step forward in advancing the technological maturity of our developments. We are ready to share the technology and open to proposals,” Danila Saranin, head of the Advanced Solar Energy Laboratory at NUST MISIS.

In close collaboration with the Thin-Film Technology R&D Center of the HEVEL Group (LLC NTC TPT), scientists solved one of the most challenging issues—sealing the solar panel to prevent degradation due to moisture and oxygen exposure. Together, they adapted the use of elastomers for panel lamination, ensuring resistance to external factors.

Enterprises that adopt perovskite panels will be able to reduce their carbon footprint, increase energy efficiency, and meet sustainability standards. All materials for prototyping the perovskite modules were supplied exclusively by Russian companies. According to the developers, pilot production could begin within the next three years.