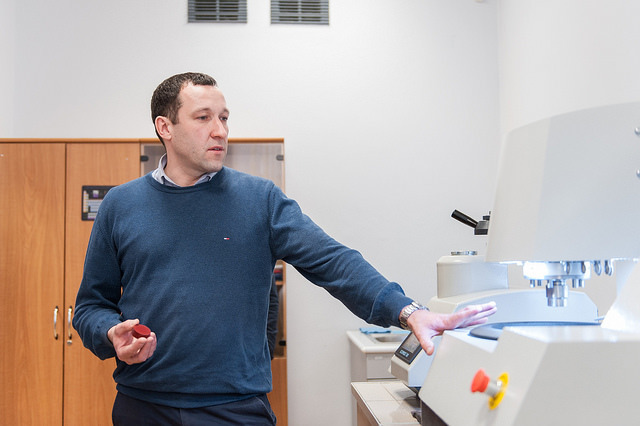

The new research & education lab “Perspective Precision Materials”, equipped with METKON equipment for sample processing and the research of precision materials, was recently opened at NUST MISIS. Vasily Bautin, Ph.D. and leading researcher at the NUST MISIS Department of Steel Metallurgy, New Production Technologies, & Metal Protection, has been appointed the lab’s head.

As Bautin described, the laboratory is equipped with almost the whole range of METKON equipment, which allows scientists to do all kinds of sample preparation work and metallographic studies. The equipment includes a precision cutting machine, an abrasive cutting machine, a press for hot pressing samples, a grinding and polishing unit, a microhardness tester, microscopes, a hardness tester, and a precision system for electrochemical polishing.

METKON was founded in 1993, and has in the time since earned the trust of notable customers like Agusta, Bosch, Eaton, Faurecia, Fiat, GKN, Hyundai, Honda, INA, Lufthansa, Mercedes Benz, Motorola, Pirelli, Schneider, Seagate, SKF, Sony, Toyota,TRW, Yamaha, and others. The creation of this new lab was possible thanks to the support of METKON’s Russian division — the LAB Solution Company. The financing came from the large-scale enterprise HILTI and the FISHER company. In the future, the lab is supposed to become self-sufficient.

The lab researchers will develop technology for the creation of finely-dispersed high-permeability powders for the production of miniature technical devices to be used with casting metals for method injections (MIM technology). Also, the research of submicron and nanoscale fractions of these materials is scheduled for the low-temperature application of advanced lithium-air batteries and therapeutic oncological hyperthermia. For a number of new materials there is no preparation or research method yet — that is why in addition to the development of materials and technologies, the development of working methods with these new materials and their introduction into the educational process is another important activity of the lab.

The lab has great plans for future equipment as well: the installation of equipment for chemical analysis is scheduled for the end of 2017, and in 2018 there are plans to install diffractometers and a scanning electron microscope.

So far in 2017, the lab`s research group has already published 4 articles in journals indexed by WoS (2 of them in top-quartile journals). The creation of a new division creates additional opportunities for the group.

That is why Andrey Travyanov, Head of the NUST MISIS College of Environmentally Sound Technologies & Engineering emphasized, “The creation of the research & education lab ‘Perspective Precision Materials’ will allow us to improve the quality of research and bring academic programs to a higher level.”

This is the fourth center which NUST MISIS has jointly launched with leading company-producers of modern research equipment: “MISIS-National Instruments”, “MISIS-INSTRON” and “MISIS-BUEHLER” already operate at the University. This kind of interaction between NUST MISIS and world-leading industrial corporations allows the university to significantly expand the possibilities of its labs, both in regularly enhancing employee skill and increasing research quality.