A science team from the Center of Composite Materials at NUST MISIS, led by research assistant Fedor Senatov, have developed a new type of polymeric bone implants with shape memory that can be used without fittings and blocking devices during surgery. One of the new implant`s characteristics is increased implant survival rate in body tissues, as well as the ability to organically degrade, and thus subsequently be replaced by natural bone tissues.

According to data from the N.V. Sklifosovsky Research Institute of Emergency Medicine, over 2,000 traumatic brain injuries require surgery annually in Russia, and up to 20% of these surgeries require surgical re-intervention because of a blundered initial implant or implant displacement occurring in the tissue.

“Young scientists from the Center of Composite Materials at NUST MISIS have created the prototype of a new polymeric implant which is coarctate, so shielded from the mechanical impact of surgery, and it ’unfolds’ at a certain temperature during the surgery”, said Alevtina Chernikova, Rector of NUST MISIS.

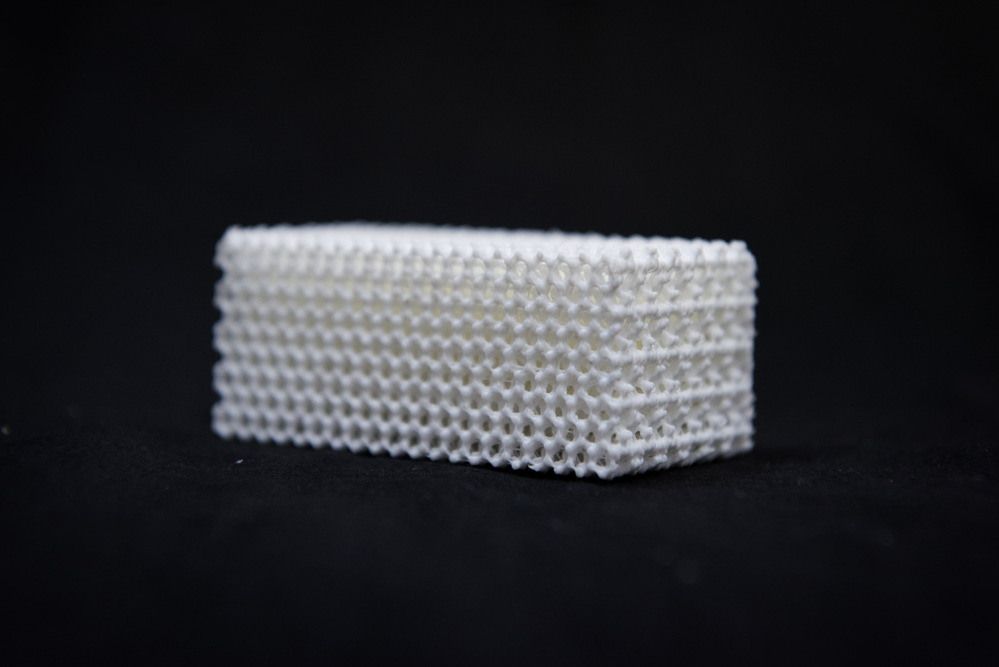

Therefore, the implant can be printed on a 3D printer at the selected dimensions, compressed twice in protective, biodegradable shelling, heated during the surgery, and eventually become securely fixed into the renovated area of bone tissue without using metal blocking devices and fasteners traditionally used in transplantology.

“We have successfully applied the shape memory effect in a polymeric composite material based on polylactide, which is a polylactic acid. A porous sample made from the composite is capable of compressing twice, and then returning to its original shape. In addition to that, the material is biocompatible: it dissolves in the body without doing any damage. Together with our colleagues from the N.N. Blokhin Russian Cancer Research Center, we have developed a technology stacking multipotent mesenchymal stromal cells (MSCs), a bioengineering structure isolated from a patient`s bone marrow, which stimulates the formation of blood vessels and tissue inside the implant, thus optimizing the process of survival and increasing the efficiency of transplantation”, explained Fedor Senatov, the head of the project.

The polymer implant developed at NUST MISIS has task geometry and high porosity; it doesn’t require additional treatment; it is tightly fixed in bone defects; and owing to the material’s properties and the use of patient`s own cells it is smoothly replaced by organic tissue.

During the first stage of the technology’s deployment, the developers are planning to use new implants in maxillofacial surgeries to replace small size bones in the skull up to 5 cubic centimeters large. The estimated cost of such a bioengineering structure sample is about