PJSC United Aircraft Corporation and NUST MISIS have agreed to use results of the University`s innovative activities to plan the company’s economic turnover.

The aim of the agreement is to ensure the strategic objectives of the corporation in the following areas: digital technologies in the production of molded pieces, industrial technologies of non-destructive testing, powder materials, and additive technologies for the manufacturing of parts.

The agreement was reached following the meeting of Sergey Korotkov, the General Designer and Vice-President for Innovations at the United Aircraft Corporation, with NUST MISIS scientists. During the meeting, JSC UAC representatives learned about the best aviation industry developments to come out of NUST MISIS.

United Aircraft Corporation works within the framework of the program of aviation development, aimed at creation of new projects, which will take the leading positions in the market in future. One of these directions is cooperation with universities.

Following the results of the meeting, Sergey Korotkov noted that there are no analogues in the world for NUST MISIS’s developments, giving the University`s partners a chance to implement projects of international importance in the fields of operational air force & civilian aircraft and space & new materials.

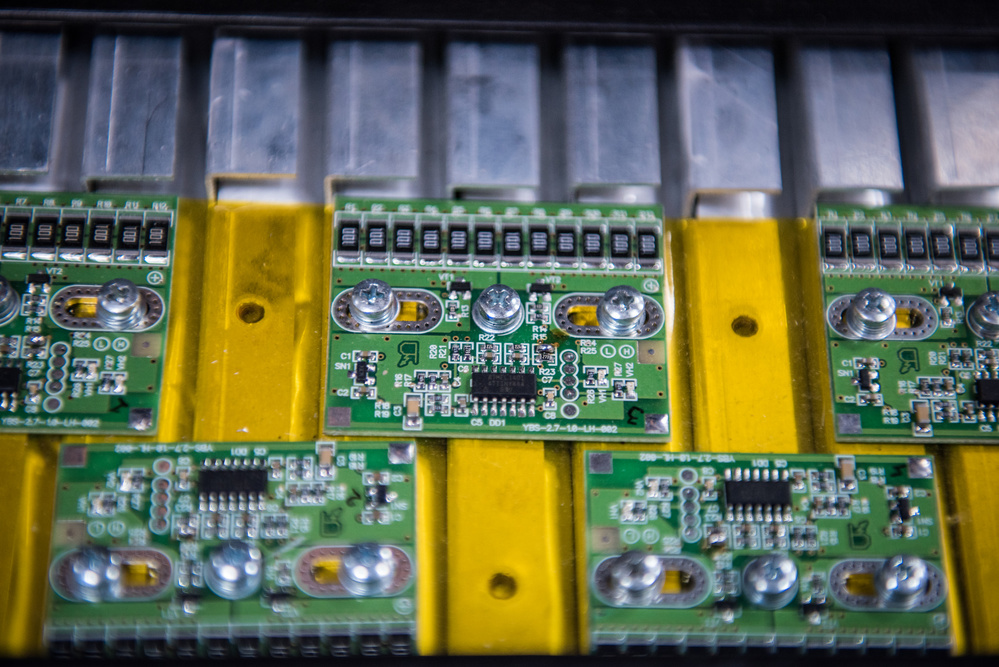

NUST MISIS scientists presented the aircraft manufacturers a series of products and technologies which can be used in the aircraft industry, including integrated energy storage based on supercapacitors and lithium-ion batteries. The innovative autonomous starter system, based on supercapacitors, is able to launch the engines of aircraft equipment at extremely low temperatures (up to —60°С).

The devices of non-destructive testing (such as a mobile diagnostic complex „Composite”), which allow a person to continuously monitor the condition and deformation of large objects — from aircrafts to nuclear power plants—attracted huge interest.

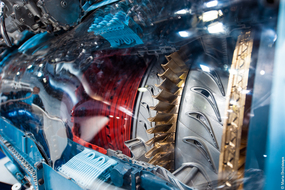

The NUST MISIS scientists also presented blades of the new generation for gas-turbine engines of civilian aircraft. Thanks to these new blades developed at NUST MISIS, the running characteristics of engines can be improved, and aircraft weight and fuel consumption can be reduced.

„Our University traditionally works closely with the aerospace complex: currently, more than 20 scientific developments are conducted at NUST MISIS by order of the industry`s leading enterprises. The creation of new ultra-light alloys, the manufacture of equipment for an on-board navigation system, and new materials for aircraft engines of the next generation are among them. In addition, the University has great experience of high-quality work execution by order of small and large companies: in 2016, NUST MISIS received R&D funds from 22 sources for a total amount of 2.5 billion Rubles”, noted Mikhail R. Filonov, NUST MISIS Vice-Rector of Research and Development.