Young scientists from NUST MISIS have developed a material with which scientists and doctors can create durable and easy-to-implement bone, joint, and muscle replacements.

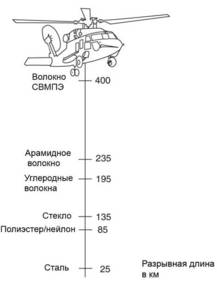

The main question when implementing any material into the body is its safety. Some substances are toxic, and some the body simply rejects. Research studies have shown that currently only artificial polyethylene with very long molecules can be used as the basis for artificial joints. Its major disadvantage however is its low durability. A science team from the Center of Composite Materials at NUST MISIS has strengthened the polyethylene with carbon nanotubes to double the material’s durability. According to calculations, the service life of an implant will be more than 15 years.

NUST MISIS researchers have created a replacement bone using high molecular polyethylene: the outer layer is solid and the interior is porous, which imitates biological structure. The bone was obtained by combining the methods of solid-phase mixing and thermopressing, and supercritical fluid was used for the creation of pores. Under certain conditions it transformed from a liquid into a gas and evaporated, leaving behind pores that have a matter of 80%.

“Such material is perfectly cut, which is very beneficial for surgeons. It also has a shape memory effect, i.e. if you squeeze it and then put it in the right place it will easily smooth itself out. So it is possible to significantly reduce the time and complexity of surgery” — said Fedor Senatov, one of the project developers, Candidate of Engineering Sciences, and research assistant at the NUST MISIS Center of Composite Materials.

Also, polyethylene may be used as artificial muscle — when cooled it contracts and when heated it expands, similar to the contraction and stretching of natural muscles. The material is planned to be used not only for humans but also for the creation of more flexible robots. The main questions are the muscle controls and the dependence of motion on the surface temperature.