A team of researchers from the Higher School of Economics, Skoltech, Moscow State Pedagogical University and NUST MISIS has made new progress in developing a lab-on-a-chip — a compact sensor device for biochemical analysis. Using serum albumin films as an example, the scientists proved that the chip surface may be modified for selective analysis of multicomponent solutions. The chip will enable to conduct an accurate blood analysis by

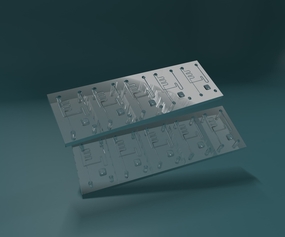

“The chip is the size of a five-ruble coin. But it is possible to create dozens of sensitive devices on its surface, bring microfluidic channels to them, modernize the surface of each sensor and create a lab-on-a-chip prototype,” Grigory Goltsman, a new technology co-developer, Chief Researcher at the NUST MISIS NTI Center’s Quantum Communications Laboratory, Professor at the National Research University HSE MIEM and Moscow State Pedagogical University, believes.

Almost any medical checkup begins with tests. Most often, patients take a general blood test. It enables to assess the hemoglobin content, the number of erythrocytes and leukocytes, etc. Sometimes, only one component, rather than the entirety of indicators, is important for the analysis. For example, it is necessary to determine the number of exosomes — microscopic extracellular vesicles (bubbles), whose increased concentration in the blood plasma indicates the development of cancer.

In a lab, it is done using sensitive sensors: their surface is modified with a special layer that binds only to specific exosomes and captures them from the solution for analysis. On some devices, the procedure requires several steps to be taken: first a layer is applied on the sensor surface, and then its quality is verified on additional equipment. The research authors demonstrated how to simplify the verification and track the surface modification using sensors on the chip itself.

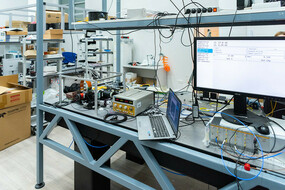

To do so, scientists conducted a series of experiments on the chip substrate: thin films of protein were applied to it. The chip consists of three parts: microfluidic channels (through which substances are pumped), a silicon nitride substrate (on whose surface films are created) and an interferometer (that measures the optical density of substances). The microfluidic channel is located above the sensitive part of one of interferometer legs.

In the course of experiments, films of protein and tannic acid were applied to the sensitive surface of photonic sensors. First, protein (bovine serum albumin) was pumped through microfluidic channels, the excess was washed with deionized water, then tannic acid was pumped and the protein layer was applied again. Each layer was analyzed using optical readings from an interferometer.

“The chip’s optical sensors have high sensitivity but low specificity to solution components. Firstly, we managed to increase specificity by modifying the sensor surface with a film of molecules sensitive to only one component from the solution. Secondly, the coating process was controlled by the sensor itself in real time,” Dmitry Gorin, a Skoltech Professor, explains.

Scientists will continue creating a lab-on-a-chip — a device for concurrent biochemical analysis of several components through the use of a minimum amount of biological fluids, for example, a single drop of blood. For this purpose, several devices are expected to be combined.

“The concurrent operation of all sensors on the device after the surface of each channel has been modified will allow to analyze

3–5 microliters of blood for the presence of markers and make a preliminary diagnosis of the patient,” Alexey Kuzin, an article co-author, HSE graduate and Skoltech postgraduate, explains.