Scientists from NUST MISIS, in collaboration with colleagues from the China University of Mining and Technology, have introduced a composite made from a combination of metal and metallic glass. This material is capable of maintaining its strength and ductility at temperatures as low as −195.75°C (−320,35°F) due to a self-heating effect. In the future, this development could help extend the lifespan of aerospace vehicles and equipment designed for operation in Arctic conditions.

As temperatures decrease, the crystalline lattice of metals becomes more brittle, limiting their use in the Far North and outer space. To address this issue, a group of researchers at NUST MISIS has developed multilayer nanocomposites that retain their mechanical properties at liquid nitrogen temperatures. The principle of operation is based on the fact that when cracks appear at the interface of the alloys, atoms begin to move, releasing heat. This heat warms the metal from within, preventing further wear.

“The emergence of cracks at the boundary between the crystalline and amorphous layers triggers atomic jumps that heat the material. This localized increase in temperature helps prevent brittle failure, which is an instantaneous fracture without noticeable deformation into many sharp fragments. The heated composite becomes more ductile and slows down crack growth. This unique behavior distinguishes the new multilayer composite material from traditional metallic alloys,” said Ivan Ushakov, Doctor of Technical Sciences and Head of the Department of Physics at NUST MISIS.

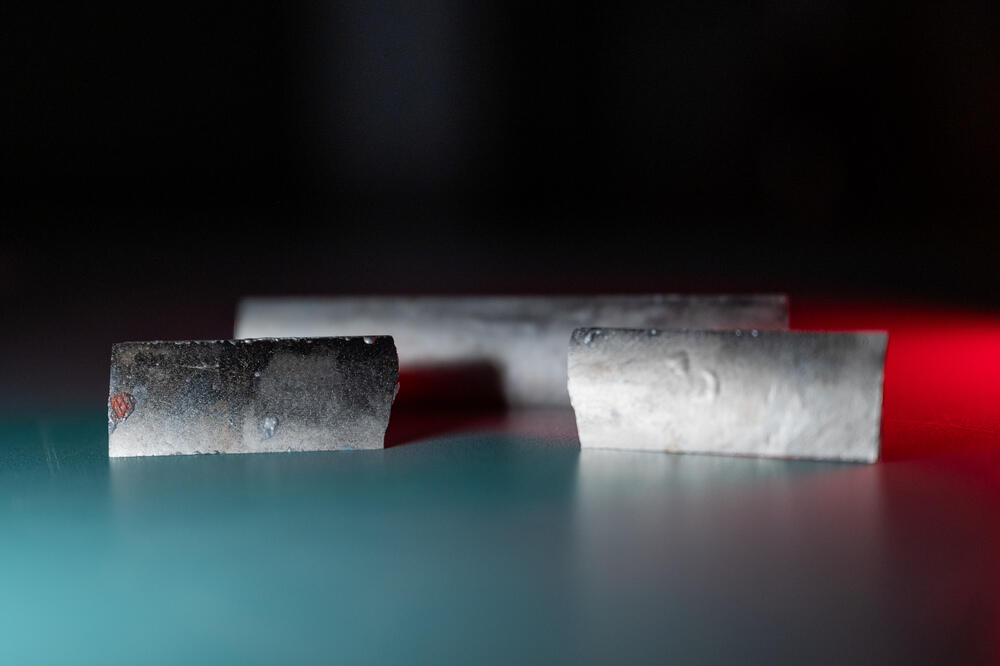

The proposed composite is a multilayer combination of low-melting crystalline metal and amorphous metallic plates. Numerical simulations performed using the finite element method confirmed that the local increase in temperature of cracks in the phase boundary zone creates optimal conditions for maintaining ductility under tensile stress. Detailed results have been published in the scientific journal Nanomaterials (Q1).

“When subjected to mechanical loads, the alloy remains intact, which is crucial for equipment in the cryogenic industry and mineral extraction in Arctic zones. Thanks to classical soldering methods, the production and processing of the composite remains relatively straightforward,” shared Ivan Safronov, associate professor at the Department of Physics at NUST MISIS.

In the future, the research team plans to improve the strength characteristics of the technology and explore radiation-resistant variants of the proposed material. This work is part of the strategic project “Materials of the Future” by NUST MISIS under the Ministry of Education and Science of Russian Federation’s Priority-2030 program (grant No. K7-2023-010), and is also supported financially by the National Natural Science Foundation of China (projects No. 51774289 and No. 52074291).