Basic Information about the Laboratory:

The Laboratory of Thermomechanical Processes was created in 2011. The laboratory equipment comprises state-of-the-art high-technology complexes for studying metallic materials and physical modelling of metallurgic processes, such as DIL805A/D deformational dilatometer and Gleeble 3800 system.

Activities of the Laboratory:

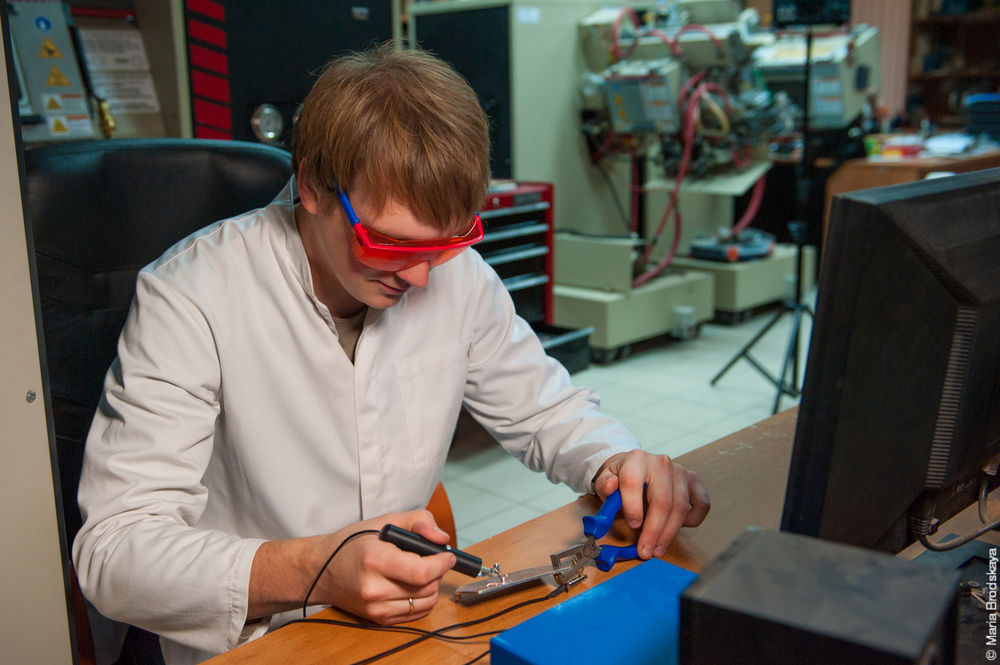

The Laboratory of Thermomechanical Processes was created within the NUST MISiS Institute of Eco-Technologies and Engineering as part of the program of enhancing scientific research directed by the key scientists in Russian educational institutions. The laboratory employs young specialists from the departments of plastic deformation of special alloys, science of non-ferrous metals, technologies and equipment for pipe production and physical chemistry. The laboratory is tooled up with the unique research equipment, such as the DIL805 A/D hardening and deformational dilatometer manufactured by Baehr Thermoanalyse Gmbh (Germany) and the Gleeble System 3800 complex for physical modelling and dynamic thermomechanical tests manufactured by DSI (United States).

Such equipment allows researching and modelling the impact of technological parameters at the stages of materials processing (from the casting and crystallization to the finishing) on the indicators of quality of finished products. Each treatment process may be modelled separately: modelling of the formation of the microstructure and features, with subsequent optimization of technological parameters of materials processing in order to minimize energy costs and financial resources.

The key tasks of the laboratory include:

- registration of phase transformations when heating and cooling;

- impact of deformation on the structure and phase transformations;

- impact of the conditions of heating and cooling on the microstructure and phase transformations;

- building up curves of mechanical features of materials;

- kinetics of hardening and softening;

- impact of deformation conditions on the ultimate microstructure and features; and

- developing technologies of producing new materials.

Andrey TravyanovHead of laboratory |