New Materials. Powder and Additive Technologies

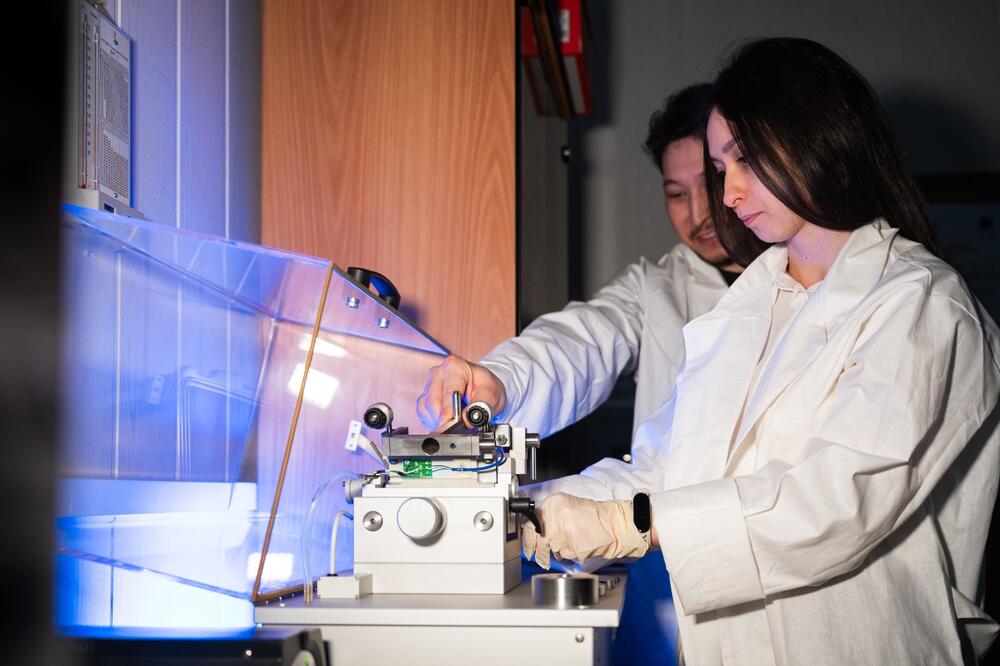

The Master’s program is focused on training specialists in research and development of advanced metallic, ceramic and composite materials and coatings for aerospace, nuclear industry and medicine. Students get acquainted with the basics and problems of materials science, high-temperature synthesis of unique alloys, 3D modeling for selective laser fusion technologies and automated manufacturing processes. Graduates of the program are in demand in various industries in Russia and abroad, continue their scientific careers in the organizations of Rosatom State Corporation, Roscosmos State Corporation, institutes of the Russian Academy of Sciences, and as postgraduates of NUST MISIS.