Scientists from the National University of Science and Technology “MISIS” developed a unique hybrid bone implant, the core of which is made of porous ultra high molecular weight polyethylene, and the shell is made of polyetheretherketone. Thanks to the combination of the unique properties of the two polymers, it was possible to create an implant that imitates the bone structure and is additionally reinforced to increase strength and elasticity. In addition, as the material consumption is reduced, the cost of such an implant will be lower than that of analogues. The article about the results of the research is published in Materials Letters.

Ultra high molecular weight polyethylene (UHMWPE) and polyetheretherketone (PEEK) are among the most frequently used materials in orthopedics. Each of them has a certain set of properties, and the choice of material is based mainly on what kind of bone defect should be eliminated. Thus, UHMWPE is traditionally used in joint replacement, and PEEK due to its greater strength, is mainly used in spinal surgery. Moreover, PEEK is a fairly expensive material, so it is used less often than UHMWPE.

Scientists from the Center of Composite Materials (NUST MISIS) applied the previously developed technology for the formation of porous biomimetic materials and conducted an experimental comparative analysis of the mechanical properties of modified UHMWPE and PEEK. As a result, they proposed a fundamentally new hybrid material that combines the useful properties of both polymers.

“We have been working with UHMWPE for quite a long period of time. Apparently, PEEK is relatively new for us. Due to the fact that we were trying to imitate natural porous bone structure in implants made of UHMWPE, we decided to also do this with PEEK. Next, we tested and compared the compression properties of the materials” — Fedor Senatov, PhD, head of the research group.

However, the high hardness of the PEEK had a negative impact on the porous modification of the material: although PEEK demonstrated good properties at compression test, it was found that when cutting (and during installation of the implant surgeon is required to “adjust” it under the edge of the defect) it starts to crumble. Crumbs in the area of implantation are unacceptable, so scientists decided to try to create a hybrid that would retain only the beneficial properties of both polymers. This is especially interesting from the point of view of imitation of the structure of the bone itself, because in the core (trabecular part) it is just softer, and on the shell (cortical part) is harder.

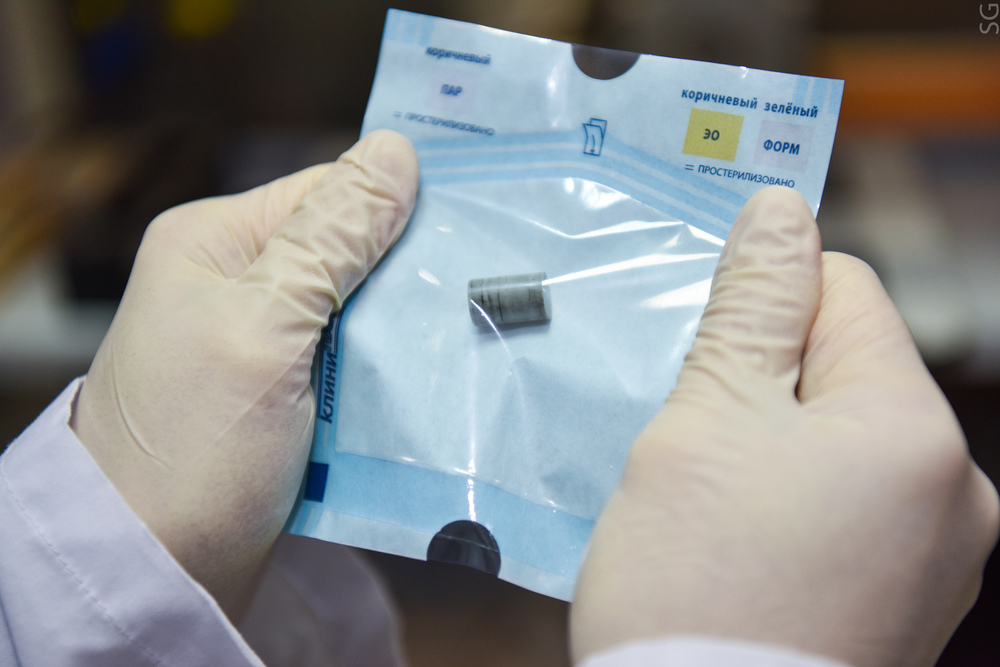

“We have created a hybrid cylindrical implant, which core and shell are made of soft porous UHMWPE and hard non-porous PEEK respectively. Tests of the mechanical strength of the implant showed that its characteristics almost completely correspond to the normal human bone: the trabecular bone has elastic modulus from 0.001 GPa to 0.002 GPa, and the porous UHMWPE has about 0.002 GPa; cortical bone has elastic modulus about 11 GPa, and PEEK has about 9 GPa” — Alexander Chubrik, 4th year student, co-author of the research.

The imitation of the human bone is not the only advantage of the implant: moreover, the porous part will allow the bone to “penetrate” the implant. This means that over time, the fixing plates can be removed, and the implant will already behave as a bone. In addition, due to the fact that the consumption of PEEK will decrease, such implants will be more affordable.

Scientists proceed the research in two directions: they test the hybrid material in vivo, and work on the attaching bioceramics to the implant surface to accelerate regeneration in the replaced bone area.