A team of Russian scientists from NUST MISIS, Tomsk Polytechnic University (TPU) and Boreskov Institute of Catalysis has suggested a new approach to modifying the combustion behavior of coal. The addition of copper salts reduces the content of unburnt carbon in ash residue by 3.1 times and CO content in the gaseous combustion products by 40%, the scientists found. The research was published in Fuel Processing Technology.

According to the International Energy Agency (IEA), coal is the predominant energy resource used as the primary fuel for power generation. According to reports, coal supplied over one-third of global electricity generation in 2020. Experts believe that despite the generally accepted energy policy aimed at reducing the share of coal usage and switching to renewable energy sources, coal, as the main type of fuel in the world, will most likely still occupy a leading position in power generation in the coming years. However, the widespread use of coal is limited by a number of problems, such as incomplete combustion of fuel and concomitant formation of toxic gases. Taking this into account, development of technologies aiming at more effective and environmentally friendly coal thermal conversion is a priority task for the coal-fired power generation industry. One of the possible solutions to improve the coal-burning efficiency is the use of catalytically active agents, such as oxides of various metals and their precursors (salts based on nitrates, sulfates, acetates, and carbonates), to intensify the combustion process.

“It is too early to give up on coal. China, for instance, relies on coal as the primary energy source for much of the 21st century despite all the ‘green’ trends. In Russia, coal accounts for a little under 20% of the country’s energy balance. Even in Great Britain, the country that’s been consistently implementing its decarbonisation policy, the demand for coal by electricity generators was registered at over 200 thousand tons in the third quarter of 2020. It is safe to say that the search for catalytic additives for improved coal-burning efficiency will continue. For us, the search has been quite successful: the use of the additives proposed by our team has been proven to significantly improve coal-burning efficiency, especially with high-ash coals,” noted Alexander Gromov, the NUST MISIS team lead and head of MISIS Catalysis Lab.

The method of coal combustion activation by metal salts is based on intensification of the combustion process and reduction of the combustion temperature. The use of the salt-based additives makes the combustion more manageable, the researchers note.

In their experiments, the scientists used copper salts as activating additives to improve reactivity of the high-ash coal fuels, such as anthracite, also known as hard coal, and semicoke. High-ash fuels are characterized by high minimum ignition and combustion temperatures, and low combustion intensity. The introduction of copper salts resulted in improved reactivity and higher burn rate of the fuel samples. It is also worth mentioning that the content of unburnt carbon in the ash residue of the modified samples was significantly lower than that in the reference samples.

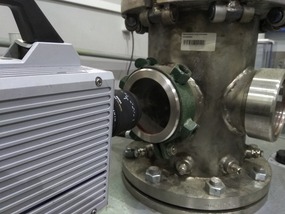

The introduction of copper nitrates, acetates and sulfates to the fuel samples was carried out by the incipient wetness procedure. Ignition and combustion experiments were then performed in a combustion chamber at temperatures of the heating medium varying from 500 °C to 700 °C.

The mechanism of combustion activation relies on the intensification of the production of gas-phase combustion products at the early stage of volatiles’ release and the generation of micro-explosions to prevent formation of slag layers that would otherwise block oxygen from the fuel.

When using oxide-based additives, dynamic contact between the fuel and the additive has to be ensured, the researchers noted. The use of salts as a catalyzing agent doesn’t require that type of contact, which makes this new method of coal modifying potentially applicable in the energy industry.

The researchers believe that the use of salt-based additives for increasing the efficiency of coal-burning could help improve fuel efficiency in energy production, minimize energy use for preheating power generating equipment and reduce carbon emissions from coal-fired power plants.