Researchers have developed a next-generation medical material made from ultra-thin aluminum oxide fibers. By altering the composition and structure, scientists can impart desired properties to the nanofibers, such as antibacterial, wound-healing, and hemostatic effects.

In modern medicine, there is a demand for bandages and patches that not only protect damaged tissues from infection but also actively participate in the healing process: delivering drugs while not disrupting the function of healthy cells. These materials must combine several properties: biocompatibility, moisture resistance, strength, and porosity.

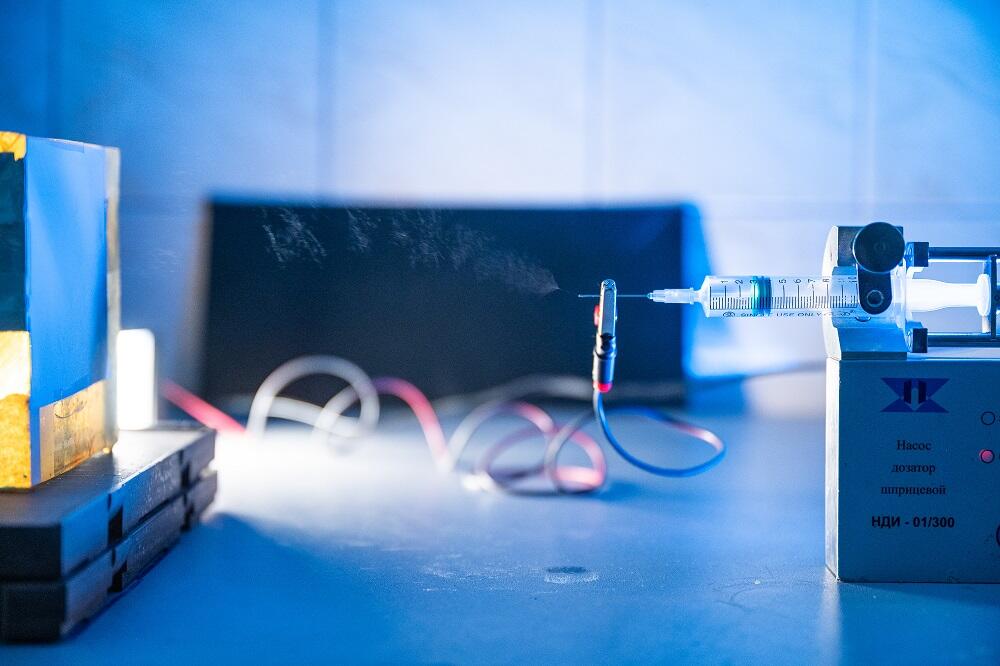

The new solution was presented by researchers from the NUST MISIS, Skoltech, and the A. N. Frumkin Institute of Physical Chemistry and Electrochemistry of the Russian Academy of Sciences. They used electrospinning technology: a solution of polyvinyl alcohol with aluminum oxide is sprayed through a very fine needle. Under high voltage, the liquid “shoots” as a jet, dries in the air, and settles as ultra-thin fibers that layer on top of one another.

“The key task was to obtain fibers as thin as possible because the thinner the fiber, the larger the total surface area of the material, which is especially important for adsorption, drug release, and interaction with tissues. We have created a model that accurately predicts the thickness of the fibers. This is critical for reproducibility and further scaling of the technology,” said Mohamad Ibrahim, a scientist of the Accelerated Particles Laboratory at MISIS.

The researchers carefully selected process parameters — voltage, distance between the needle and receiver, concentration of aluminum oxide — and reduced the average diameter of the fibers to 178 nanometers. Since pure polyvinyl alcohol dissolves easily in water and poorly holds its shape, specialists added a crosslinking agent to the aluminum oxide nanoparticles, after which the material retained its structure even after soaking. The details are published in the journal Emergent Materials (Q2).

“The resulting composite has properties that were previously difficult to combine in a single material: water resistance, biocompatibility, high surface area, and mechanical stability. By using different compositions, it is possible to create materials for a variety of applications. This opens the way to the development of next-generation medical bandages with drug delivery, disinfection, and hemostatic capabilities,” noted Alexey Salimon, head of the Department of Physical Chemistry at NUST MISIS.

Biotests confirmed that the aluminum oxide composite is safe for human connective tissue cells. This development is promising not only for creating bandage materials. In collaboration with the College of Biomedical Engineering at NUST MISIS, staff from the Department of Physical Chemistry plan to create matrices for skin regeneration as well.

The work is supported by a grant under the Ministry of Education and Science of Russia’s “Priority-2030” program (project No. K1-2022-032).