Specialists at NUST MISIS, together with the LIFT Research Center, have created a new system for coating surgical threads with antibacterial compounds. The joint project, aimed at developing medical suturing materials capable of gradually releasing embedded drugs, is being carried out with the support of Gazprombank under the Priority-2030 program.

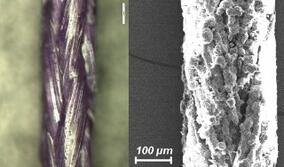

As part of the project, an efficient technology has already been developed for producing various types of polymer-based surgical materials. The first product, however, will be surgical sutures with an antibacterial coating that provides a long-lasting antiseptic effect. A prototype line of laboratory samples has already been produced, demonstrating sustained bactericidal effectiveness for more than two weeks.

Sutures and mesh endoprostheses are polymer materials enhanced with micro- and nanocarriers that enable controlled drug release at the site of surgery. Depending on the applied coating, these materials can possess antiseptic, anti-inflammatory, and wound-healing properties.

The project also includes the development of unique production equipment for applying drugs onto fibers. This system is now in its final stages and is scheduled to launch on October 9, 2025.

“NUST MISIS specialists have designed a unit for applying drug-based coatings to surgical threads. It was developed in record time — just six weeks — and has already produced the first modified threads. The university is now working on an industrial prototype that will increase production capacity tenfold,” Dr. Fedor Senatov, Director of the Institute of Biomedical Engineering at NUST MISIS.

“For us, it is critically important that we are talking about a real product that can reduce the risk of postoperative complications and accelerate patient recovery. Our joint project with NUST MISIS, supported by Gazprombank, demonstrates that the medicine of the future is being created today. We firmly believe that science must serve people, and technology must safeguard health and save lives. Partnerships like this not only generate innovation but also advance medicine itself — because it concerns each of us,” Mikhail Nasibulin, CEO of the LIFT Research Center.

At present, Russia has limited or no industrial-scale production of sutures and mesh endoprostheses with specialized coatings, forcing domestic companies to rely on imported fibers. For the first time, an industrial production line will be established for new surgical materials, paving the way for introducing innovative medical devices into clinical practice—devices that can significantly speed up and reduce the cost of postoperative rehabilitation.

“Our collaboration with NUST MISIS is a vivid example of how science and business should work together. The project was executed brilliantly and in a very short timeframe. Initiatives like this deserve the highest level of support, and we are fully open to further cooperation. It is vitally important for us to build an open information environment so that projects of this kind can find development partners in a timely manner,” Dmitry Zauers, Deputy Chairman of the Management Board at Gazprombank.