NUST MISIS scientists, for the first time, have come up with a technology for 3D printing of thin-walled tungsten elements of complex shape. The new method allows printing structures with a wall thickness of 100 micrometers (μm). For comparison, the thickness of human hair is up to 120 μm. The proposed technology can be used to manufacture parts for experiments on Russian particle accelerators.

Tungsten is a refractory metal critical to the success of many modern industries, from metalworking and aerospace to engine building and medicine. The melting point of tungsten is 3,422 °C, which makes it the most refractory of the known metals. It absorbs radiation effectively and is not susceptible to corrosion, but exhibits extreme brittleness at room temperature, making it difficult to machine.

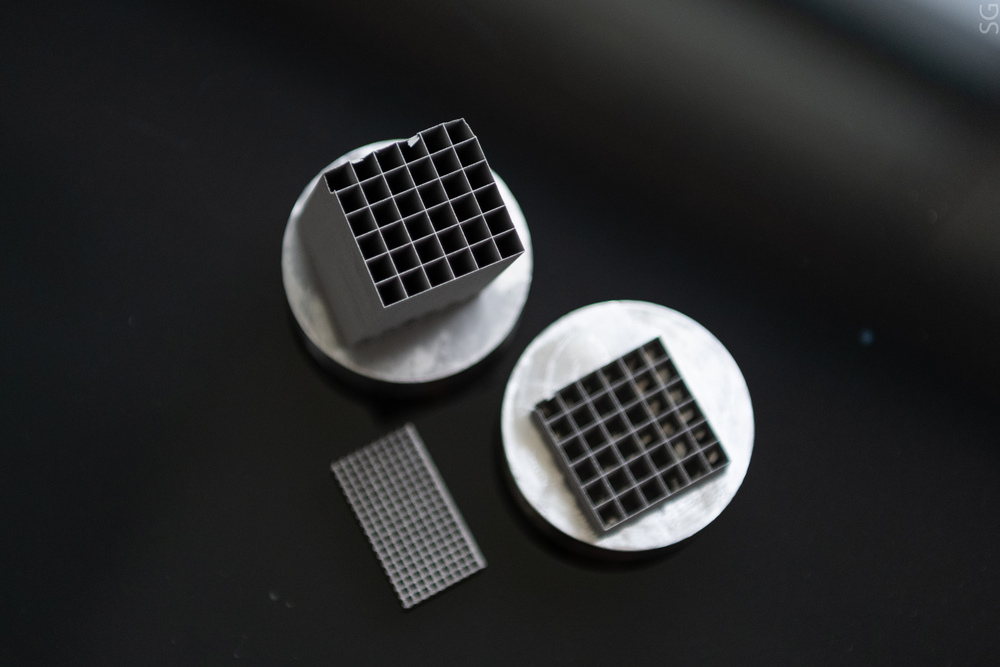

One of the most promising ways to create tungsten parts of complex shape is 3D printing. NUST MISIS scientists, for the first time, managed to obtain a part of complex shape with a wall thickness of 100 microns (0.1 mm) from tungsten powder. Such printing was implemented by the method of selective laser melting, a technology that can be described in a simplistic way as melting a powder with a laser into a 3D design of a given shape.

“Despite the refractory properties of tungsten, we managed to select the technological parameters of 3D printing for the production of thin-walled parts from it using the technology of selective laser melting. The study of the conditions for the formation of a melt bath for tungsten under the influence of laser radiation allowed to increase the resolution of tungsten printing to the physically possible limit, ” Ivan Pelevin, researcher at the NUST MISIS Catalysis Lab.

In the future, the technology can be used to create a new generation of high energy particle detector — a calorimeter — for experiments on the Large Hadron Collider in CERN and on Russian particle accelerators. The radiation absorber made of thin-walled tungsten is able to effectively absorb high energy particles and form a so-called electromagnetic rain, which is formed when high-energy particles interact with the absorber substance. A calorimeter with such an absorber will increase the particle flux density in experiments and, in the future, gain new knowledge about the properties of hadrons with heavy quarks.

In addition, 3D screens made of tungsten can be used as an anti-dispersion matrix for proton radiation therapy — an innovative method of treating cancer using an excreted beam of charged particles on medical accelerators.