Researchers at NUST MISIS have proposed a new technology for applying protective coatings to marine and coastal infrastructure, as well as to industrial equipment operating in high-humidity environments. The team discovered that the best corrosion resistance is achieved by applying high-entropy coatings using the method of electro-spark alloying.

When in constant contact with water, any alloy oxidizes. Even stainless steel cannot always withstand such conditions: its surface is damaged by friction and the impact of seawater salts.

“One of the key missions of NUST MISIS as a recognized leader in materials science is to ensure the creation of materials that combine the properties necessary for real-world industrial applications. The new protective coating technology developed by MISIS researchers under the leadership of one of Russia’s and the world’s leading materials scientists, Professor Dmitry Shtansky, Doctor of Physical and Mathematical Sciences, can be used by industrial companies to protect marine and coastal infrastructure,” NUST MISIS Rector Alevtina Chernikova.

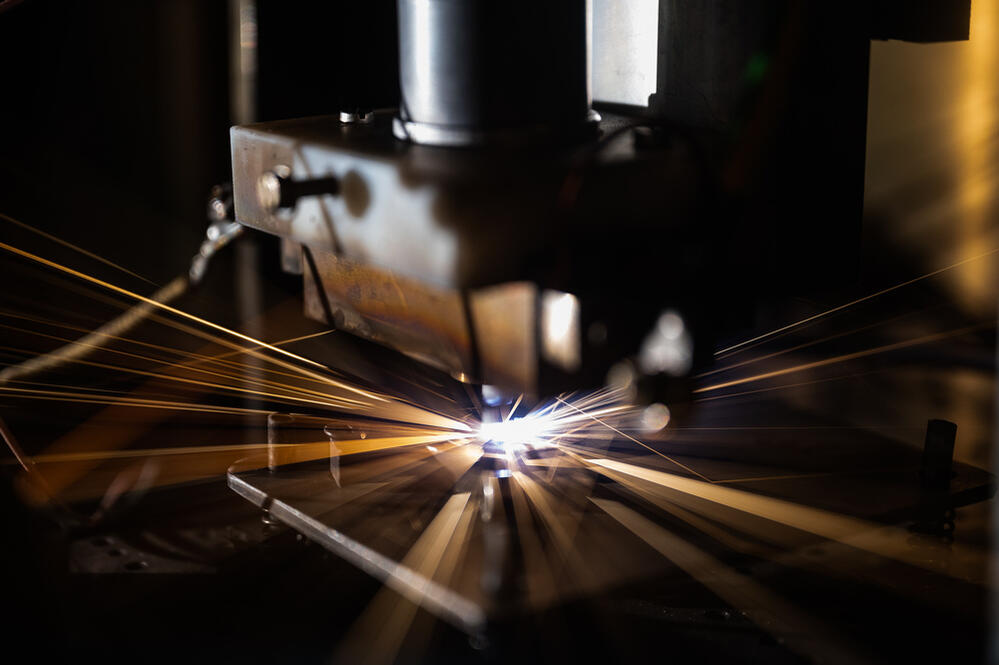

To extend the service life of components exposed to corrosive environments, the MISIS team proposed applying an amorphous coating based on a high-entropy alloy with added boron, using the method of electro-spark alloying.

Konstantin Kuptsov, PhD in Engineering, Senior Researcher at the MISIS-ISMAN Research and Education Center for Self-Propagating High-Temperature Synthesis, explains: “An amorphous structure is a state of matter where atoms are arranged randomly, without a clear crystalline lattice. This disorder makes the material more resistant to corrosion, since aggressive environments cannot easily penetrate its structure. We created a material with characteristics comparable to stainless steel, but up to four times harder. Such coatings can extend the lifetime of equipment operating in seawater — for example, pumping systems, impellers, valves, shafts, and more. In the long run, this will help companies reduce maintenance and repair costs.”

The properties and structure of the coating can be fine-tuned by varying the alloy composition and post-processing conditions. In some cases, the coating is optimized for strength and corrosion resistance, making it suitable for parts that are constantly submerged in water. In others, it is made especially hard to provide better protection against friction and wear. The results have been published in Materials Today Communications (Q1) and Journal of Alloys and Compounds (Q1).

“The development of high-entropy materials, including amorphous ones, is a highly promising area of modern materials science. They are characterized by high hardness and effectively resist wear, corrosion, and aggressive environments — from chemical factors such as seawater salts to atmospheric and thermal effects,” said Professor Dmitry Shtansky, Dr. Phys.-Math.Sci., Head of the Department of Powder Metallurgy and Functional Coatings, and Director of the NUST MISIS Center for Inorganic Nanomaterials.

The research was supported by the Russian Science Foundation (grant No. 20-79-10104-П).