An international research team has come up with an innovative method for metal recovery from industrial waste. The new method allows the simultaneous recovery of multiple metals from waste oxides in a single process. This novel route will lower the burden on waste storage facilities with significant contributions to the economic and environmental sustainability of industrial waste management. The study was published in Journal of Environmental Management. This work is the first in a series of studies aimed at developing cost-effective and environmentally sustainable solutions for industrial waste recycling.

Some of the major industries such as coal and biomass-based power generation, iron and steel sector, aluminium production, water treatment etc. are known to produce huge amounts of aluminium and iron oxides rich wastes, e.g., fly ash from combustion of coal and biomass, mill scales, red mud, biochar (the char coproduct from the thermochemical processing of biomass utilized as a soil amendment and/or carbon sequestration agent), water treatment residues. Produced in hundreds to billions of tonnes, these wastes cause immense disposal issues. Leaching of metals into atmosphere through improper disposal can result in serious environmental damage and adverse effects on humans. However, current waste management methods are economically unviable and environmentally unsustainable.

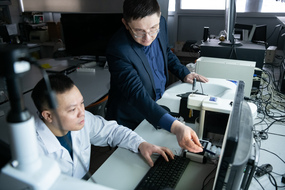

These industrial wastes can be a valuable secondary metals resource, scientists believe. A group of researchers from NUST MISIS, the University of New South Wales, Plekhanov Russian University of Economics, Universidad Andres Bello, Institute of Minerals and Materials Technology under the Council of Scientific and Industrial Research of India have developed a new technology that allows the simultaneous recovery of multiple metals from waste oxides in a single process, which, in turn, helps reduce the costs of waste processing.

The scientists used carbothermal reduction to extract metals from industrial wastes rich in oxides of iron, aluminium, silicon and other metals.

“Simply put, we used carbon and high temperatures to extract metals from the oxides in the waste. Key innovation of this study was to lower the reduction temperature for alumina, thus making it possible to recover it simultaneously along with iron and silicon that have lower reduction temperature,” noted Yuri Konyhov, Deputy Head of the Department of Functional Nanosystems and High-Temperature Materials at NUST MISIS.

This novel approach could significantly enhance economic and environmental sustainability of managing industrial waste as it allows mixing various types of waste together and processing of large amounts of waste, the researchers believe.