The solution proposed by the NUST MISIS scientists opens up new prospects for the creation of safer and biocompatible bone implants. It was found that lysostaphin protein transfers antibacterial properties to bioceramics in the course of application, effectively inhibits the growth of staphylococcus strains and destroys bacterial biofilms. Such ceramics may be used as the primary component of implantable materials. The work findings were published in the international scientific Pathogens journal.

In the surgical treatment of osteomyelitis or osteoplasty for open fractures, staphylococcus aureus is the most common cause of infection. Due to the ubiquity of antibiotic-resistant strains of S. aureus, treatment with standard antimicrobials is becoming increasingly difficult. The efficacy of antibiotics is also negatively affected by the ability of microorganisms to form more drug-resistant biofilms on medical implants. According to the medical records in the United States, infection develops after implantation in about 5% of cases. Moreover, if standard antibiotic therapy is conducted, the infection recurrence occurs in

The impregnation of implants with enzymes that destroy bacterial cell walls may become one of advanced ways to reduce the percentage of infectious complications in osteoplasty. Biocompatible ceramics based on diopside from silicate, calcium and magnesium (CaMgSi2O6) have a great potential in the field of bone prosthetics and have only recently been proposed for use in regenerative medicine. The NUST MISIS synthesized such bioceramics and examined their structural characteristics. A high biological activity and biocompatibility are explained, among others, by a high biomineralization ability of diopside.

“In the first few hours after implantation, the diopside surface is covered with a layer of apatite. On top of that, diopside releases Ca2+, Mg2+ and SiO32- ions, which encourage cell multiplication and their transformation in the regeneration zone exactly into bone tissue,” Inna Bulygina, a research project engineer at the NUST MISIS Research and Educational Center for Biomedical Engineering, explains, “These properties make diopside potentially promising as a replacement for calcium-phosphate ceramics.”

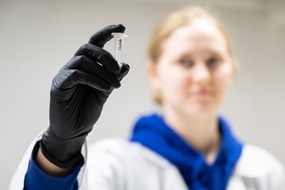

A recombinant (a protein whose DNA is created artificially) lysostaphin incorporated into a diopside powder acts on antibiotic-resistant (MRSA) and antibiotic-sensitive (MSSA) strains of staphylococcus aureus with the same efficacy and demonstrates synergy when used concurrently with conventional antibiotics. After application of lysostaphin, the ceramics were examined at the Gamaleya National Research Center for Epidemiology and Microbiology of the Ministry of Health of the Russian Federation.

“Lysostaphin cleaves pentaglycine cross-bridges in the peptidoglycan of S. aureus, which leads to the death of bacterial cells,” Anna Karyagina, Dr. Sci. (Biol.), Professor, Chief Researcher at the Laboratory of Biologically Active Nanostructures at the Gamaleya National Research Center for Epidemiology and Microbiology, Professor at the NUST MISIS Research and Educational Center for Biomedical Engineering, explains, “This highly efficient protein may be produced in large quantities by microbiological synthesis and used to saturate a wide variety of materials. For example, it may be successfully used to cover titanium implants for dentistry, maxillofacial surgery and surgical treatment of long bone fractures and spinal injuries and included in the composition of injectable hydrogels used in minimally invasive procedures for osteoplasty.”

As opposed to traditional antibiotics, lysostaphin effectively kills both actively growing and dormant bacterial cells. However, this enzyme is only active against S. aureus and, to a lesser extent, coagulase-negative staphylococci. Most other antibacterial enzymes also have a relatively narrow focus. Further studies shall look for the possibility of loading diopside with two or more antibacterial proteins with different specificities. The work of studying antibacterial and antibiofilm properties of lysostaphin incorporated into diopside particles was done under the project financed by the Russian Science Foundation.