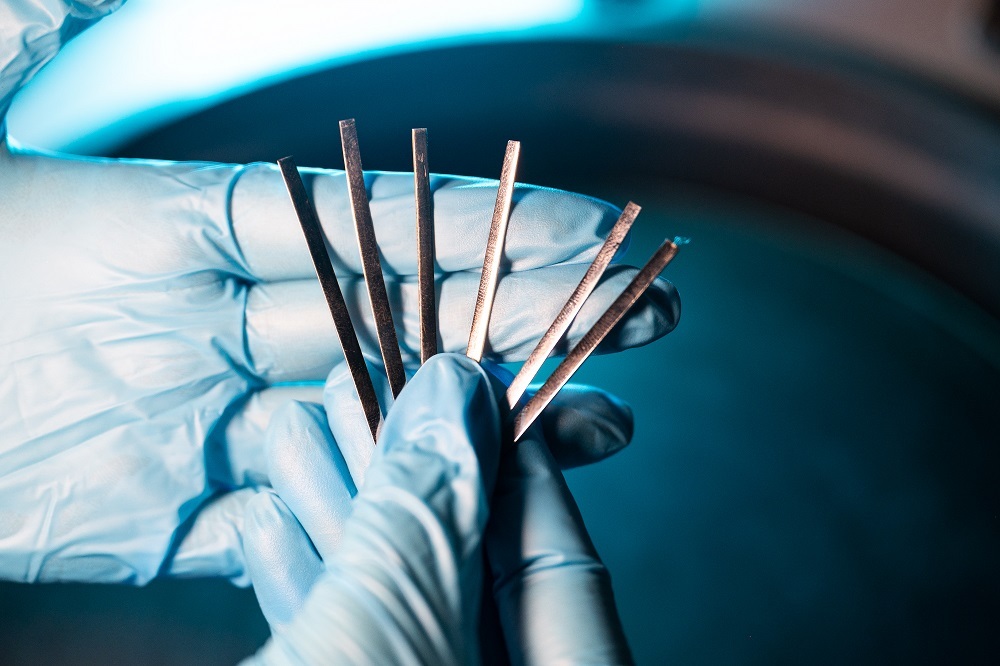

Researchers at the MISIS University have patented a shape memory alloy for biodegradable bone implants based on an iron-manganese-silicon (Fe-Mn-Si) system. It possesses high biomechanical compatibility with bone tissue and the required rate of dissolution, making it a promising material for use in traumatology, orthopedics and maxillofacial surgery.

Currently, there are materials based on magnesium or zinc that can dissolve in the body, but they have lower mechanical properties. Additionally, the biodegradation rate of magnesium is excessively high, potentially compromising the integrity of the implant before the complete recovery of bone tissue. Moreover, the decay of magnesium is accompanied by the release of gaseous hydrogen, which can be harmful to people.

Compared to these substances, iron-based alloys have superior mechanical properties but low biodegradability. To address this drawback, manganese and silicon are used as alloying elements.

“The development of biodegradable implants is a relevant sphere in medicine. In some cases, after the restoration of damaged bone tissue, implants need to be removed from the body, requiring a second operation. This is traumatic for the patient and entails additional costs. Furthermore, the long-term use of implants made of stainless steel, cobalt-chromium alloys, titanium alloys and other traditional materials can lead to negative consequences such as implant loosening, wear, restriction of bone tissue growth, allergic reactions and in some cases even oncological diseases,” says the patent author Pulat Kadirov, Dr.-Ing., an engineer at the Metal Forming Department at NUST MISIS.

In addition to biocompatibility with bone tissue and specific physico-mechanical properties, the material for implants should contribute to tissue healing and regeneration with subsequent natural dissolution in the patient’s body.

“In the development of biodegradable alloys, the proper selection of the dissolution rate is a crucial task to ensure high mechanical properties for the required time until the bone tissue is fully restored, and the implant experiences a significant load. Therefore, in the course of our research, we scrutinize both the mechanical and corrosion-electrochemical behavior of our materials,” says the co-author of the patent Yulia Zhukova, Dr.-Ing., a leading researcher at the Center of Nanomaterials and Nanotechnologies at MISIS University.

It is known that the application of various thermomechanical treatment methods, including hot and cold rolling with subsequent post-deformation annealing, significantly enhances the functional properties of the alloy. Scientists have found that after hot rolling at 800°C followed by water quenching, the best biomechanical compatibility of the material with bone tissue is achieved. Mechanical properties such as ultimate tensile strength, yield stress, relative elongation to failure and the required biodegradation rate of 0.47 mm/year are significantly increased.

Alevtina Chernikova, the rector of the MISIS University, noted: “Creating new materials and technologies in the field of biomedicine is one of the key directions of the university’s activities within the ‘Priority 2030’ program. For several years, university scientists have been developing materials that can be applied in the therapy of various diseases in surgery, traumatology and orthopedics. The new alloy for biodegradable bone implants based on the iron-manganese-silicon system, created at NUST MISIS, will improve the quality of life for thousands of patients.”

MISIS specialists plan to scale up the production of blanks of this alloy for industrial production while maintaining the required quality. Additionally, as part of an agreement with the Tomsk National Research Medical Center of the Russian Academy of Sciences, medical preclinical tests of in vitro and in vivo biocompatibility are scheduled to be completed by the end of this year.