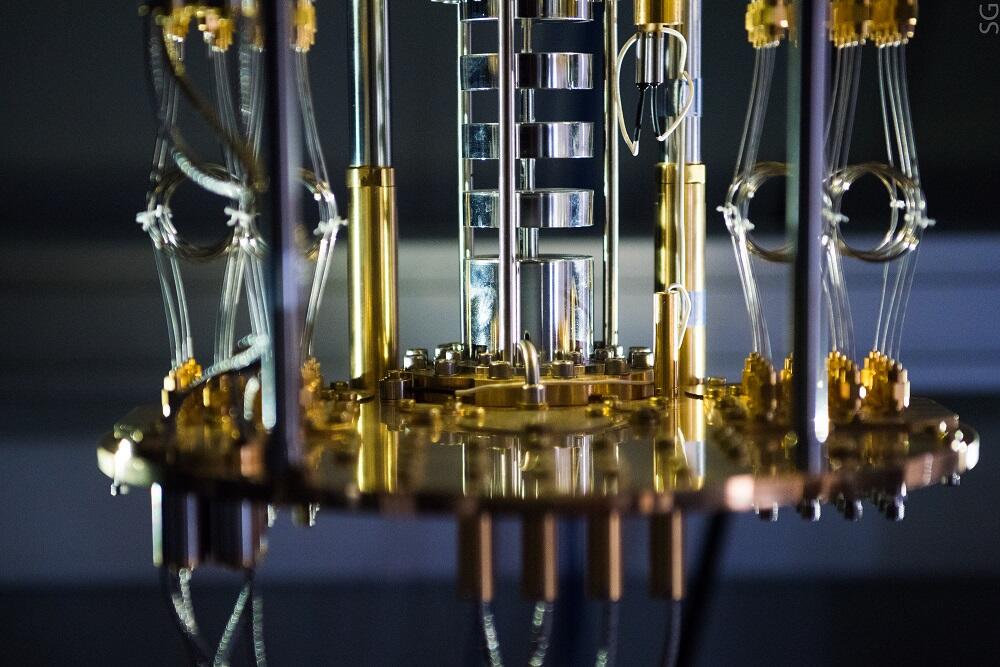

Reaching a New Level: MISIS and Russian Quantum Center Scientists Explain How to Simplify Quantum Computing

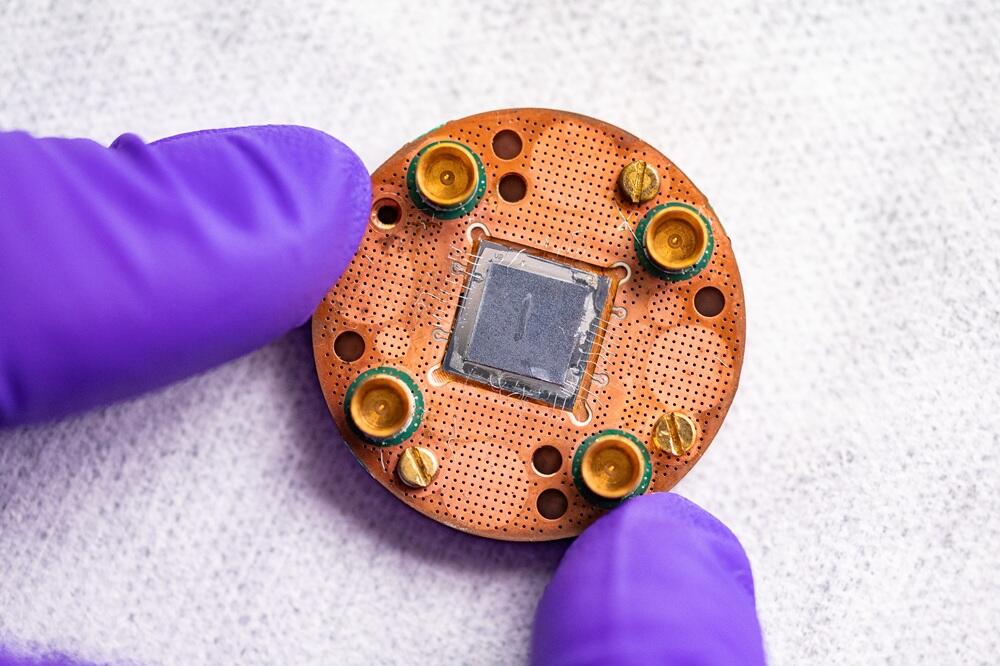

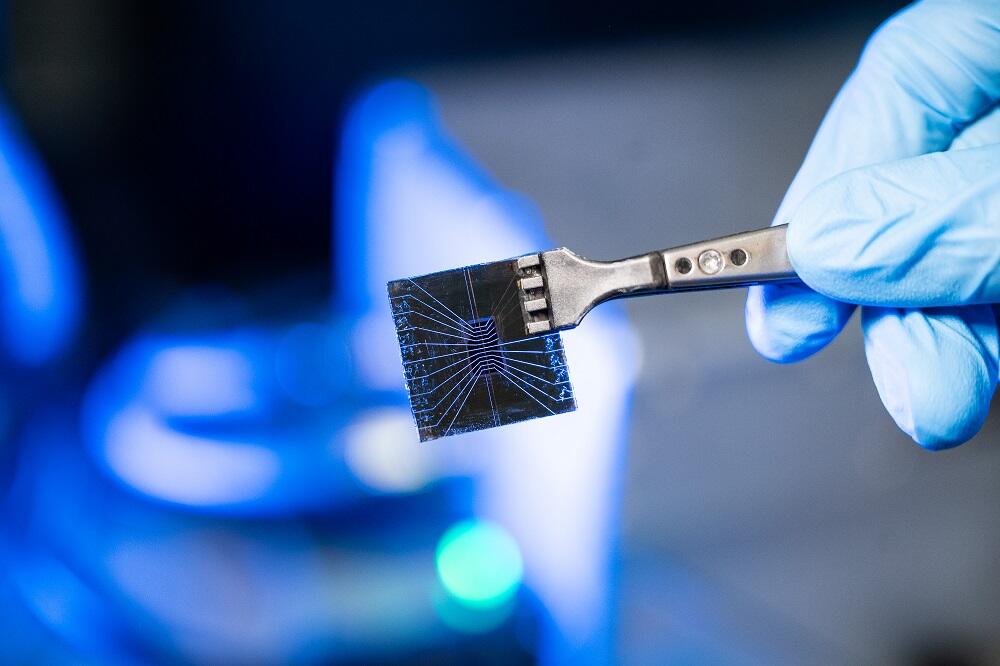

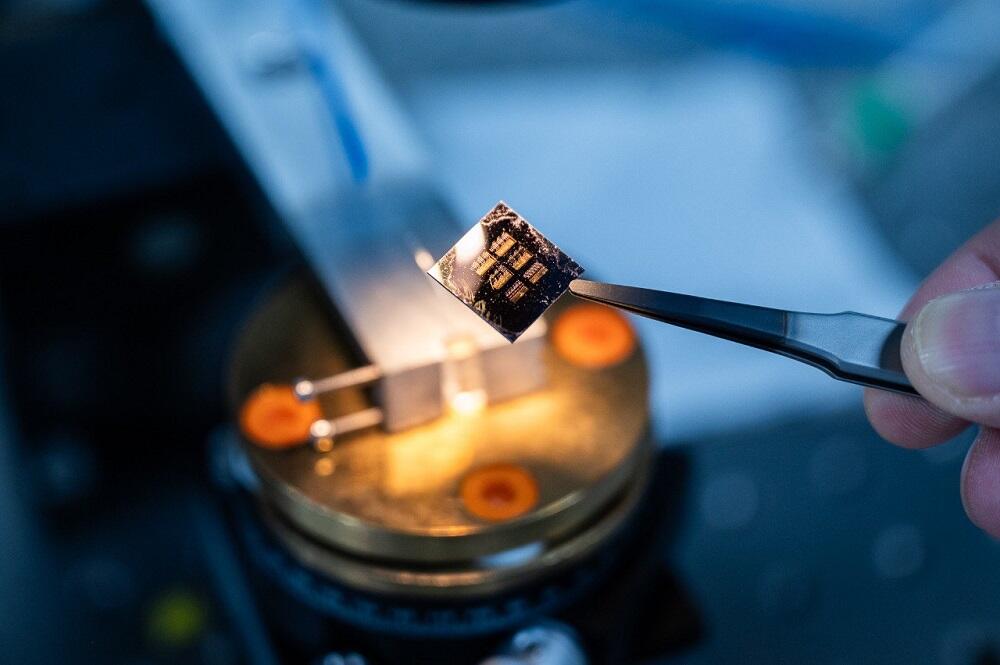

Physicists from the National University of Science and Technology MISIS and the Russian Quantum Center (RQC) have systematized modern approaches to implementing quantum algorithms using multidimensional quantum systems—qudits—and demonstrated how engaging additional energy levels of quantum carriers can simplify the execution of complex quantum operations and reduce their number compared to standard qubit-based schemes. Such approaches can improve the efficiency of quantum computing and bring the practical application of quantum algorithms closer in areas such as optimization, data processing, and the modeling of complex systems.